What is the Best Machine for Food Packaging: A Comprehensive Guide

The food packaging industry has seen remarkable growth in recent years, driven by rising consumer demand for convenience and safety in food products. According to a report by MarketsandMarkets, the global food packaging market is expected to reach $500 billion by 2025, growing at a compound annual growth rate (CAGR) of 5.3% from 2020. This growth underscores the critical role of machine packaging food technologies, which enhance efficiency, extend shelf life, and reduce waste. As advances in automation and smart technology continue to evolve, selecting the right machine for food packaging has become essential for manufacturers looking to remain competitive. This comprehensive guide will delve into the various types of machines available, their features, and how to determine the best fit for your specific food packaging needs.

Understanding the Different Types of Food Packaging Machines

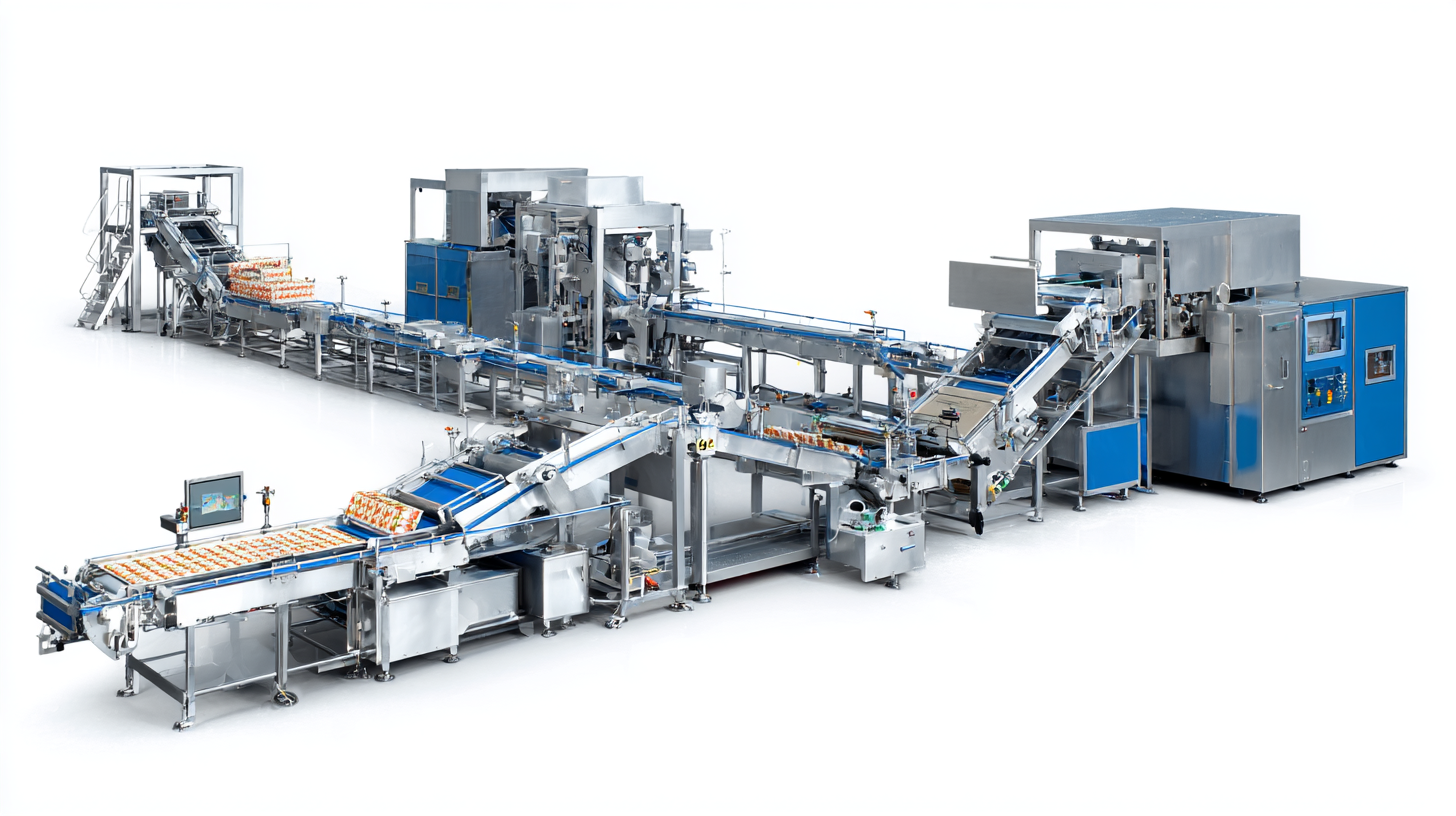

When exploring the myriad types of food packaging machines, understanding your specific needs is crucial. The market now offers various technologies, from thermoforming machines designed for packaging meat products to advanced robotic systems that streamline packaging processes across multiple industries. For instance, entry-level thermoforming machines can provide cost-effective solutions for smaller operations, ensuring high-quality packaging without significant investment.

Tips: When selecting a food packaging machine, consider the type of products you plan to package. Different machines excel in various areas, such as speed, efficiency, and versatility. Additionally, assess the machine's compatibility with your current production line to avoid costly upgrades.

The growing emphasis on sustainability is driving innovations in food packaging. Many manufacturers are integrating eco-friendly materials and practices into their machinery. Staying updated on market trends can guide you towards making informed decisions that align with consumer preferences for sustainable packaging solutions.

Tips: Look for packaging machines that minimize waste and utilize recyclable materials. Also, be proactive in adapting to trends for a competitive edge in the evolving food packaging landscape.

What is the Best Machine for Food Packaging: A Comprehensive Guide

| Type of Machine | Key Features | Advantages | Disadvantages | Ideal Use Cases |

|---|---|---|---|---|

| Vacuum Sealers | Removes air, seals bags tightly | Extends shelf life, preserves flavor | Requires specific bags, limited volume | Meat, seafood, household use |

| Heat Sealers | Uses heat to seal plastic bags | Easy to use, minimal training needed | May require pre-made bags | Snacks, frozen foods, retail |

| Filling Machines | Automates filling processes | High speed, reduces labor costs | High initial investment | Liquid foods, sauces, beverages |

| Labeling Machines | Applies labels on packages | Improves branding, automation | Initial setup can be complex | Bottles, jars, cans |

| Case Packing Machines | Packs items into boxes | Increases efficiency for bulk | Large footprint, expensive | Bulk foods, multi-pack products |

Key Features to Consider When Choosing a Food Packaging Machine

When selecting a food packaging machine, understanding the key features based on specific needs is crucial. The market offers a spectrum of options, including fully automatic and semi-automatic machines, each catering to different efficiencies and production volumes. For instance, fully automatic machines typically provide higher output and reduced labor costs, making them ideal for large-scale operations. In contrast, semi-automatic machines may be more suitable for smaller businesses or niche products that require flexibility in production scales.

Product type also plays a significant role in the decision-making process. Equipment for filling small bags, large bags, and bulk bags varies in complexity and functionality, with each designed to serve particular packaging needs within the food and beverage industry, feed industry, and other sectors. As the global food packaging equipment market is projected to reach $28.29 billion by 2032, with a compound annual growth rate of 3.6%, businesses must also consider sustainability and compliance with environmental standards. Reports highlighting the impact of food packaging, such as the collaboration between industry leaders for environmentally friendly takeaway packaging, underscore the industry's shift toward greener practices, influencing machine innovations and consumer preferences alike.

Comparing Manual vs Automatic Food Packaging Solutions

When choosing the best machine for food packaging, understanding the differences between manual and automatic solutions is crucial. Manual food packaging machines offer a hands-on approach, allowing operators to control each step of the process. They are typically more affordable and easier to set up, making them ideal for small-scale operations or businesses just starting. However, they can be time-consuming and labor-intensive, which may limit production capacity and efficiency.

On the other hand, automatic food packaging solutions are increasingly gaining popularity, especially with the forecasted growth in the food and beverage sector. These machines streamline the packaging process, significantly reducing labor needs while boosting productivity. As highlighted in recent market analysis, the flow packaging market is set to reach over $18.4 billion by 2024, driven by advances in automatic solutions that enhance speed and reliability. For businesses looking to scale, investing in automatic machines could provide a critical competitive edge in the rapidly expanding food packaging landscape.

Comparison of Manual and Automatic Food Packaging Solutions

Top Brands in the Food Packaging Machine Industry

The food packaging machine industry is currently experiencing robust growth, with the market expected to surpass USD 69.58 billion by 2032, showcasing a compound annual growth rate (CAGR) of over 4.5% from 2025 onwards. This impressive growth can be attributed to the increasing demand for packaged food products and advancements in packaging technology. Companies are investing significantly in innovative packaging solutions to enhance efficiency and maintain product freshness, thereby driving the evolution of modern food packaging machinery.

In 2023, exports of food processing and packaging machinery reached record levels, with notable growth from manufacturers in various regions. Strapping machines, which play a vital role in warehouse operations, are among the key equipment being prioritized by top manufacturers. Additionally, the tube filling machine market is gaining traction, with several companies dominating the sector, showcasing the competitive landscape of food packaging machinery. As businesses seek to improve their operational efficiency and respond to evolving consumer demands, leading manufacturers continue to innovate and adapt their offerings in this dynamic industry.

Maintenance Tips for Ensuring Longevity of Your Food Packaging Equipment

Proper maintenance of food packaging equipment is crucial for ensuring its longevity and efficiency. According to a report by Smithers Pira, nearly 40% of packaging machinery failures can be attributed to neglecting regular maintenance schedules. To mitigate this risk, it's essential to implement a proactive maintenance plan that includes routine inspections and servicing. Regular cleaning, lubrication of moving parts, and timely replacement of worn components can significantly extend the lifespan of your equipment. For instance, maintaining proper tension in belts and chains can reduce friction, thereby reducing wear and prolonging service life.

In addition to routine maintenance, training your staff on best practices is critical. Studies by the Institute of Packaging Professionals show that companies with well-trained personnel experience 15% less downtime compared to those who do not prioritize employee education. Encouraging staff to follow the manufacturer's guidelines for equipment operation and maintenance can not only enhance productivity but also foster a culture of care and respect for the machinery. By investing resources into both maintenance checks and employee training, food packaging operations can achieve seamless performance and maximized asset longevity.