2026 Best Stainless Steel Wire Mesh Options to Consider?

When choosing the right stainless steel wire mesh, one may encounter many options. Industry expert Dr. Linda Graham once stated, "Quality and durability are paramount when selecting stainless steel wire mesh." This wise advice guides many in the decision-making process, emphasizing importance.

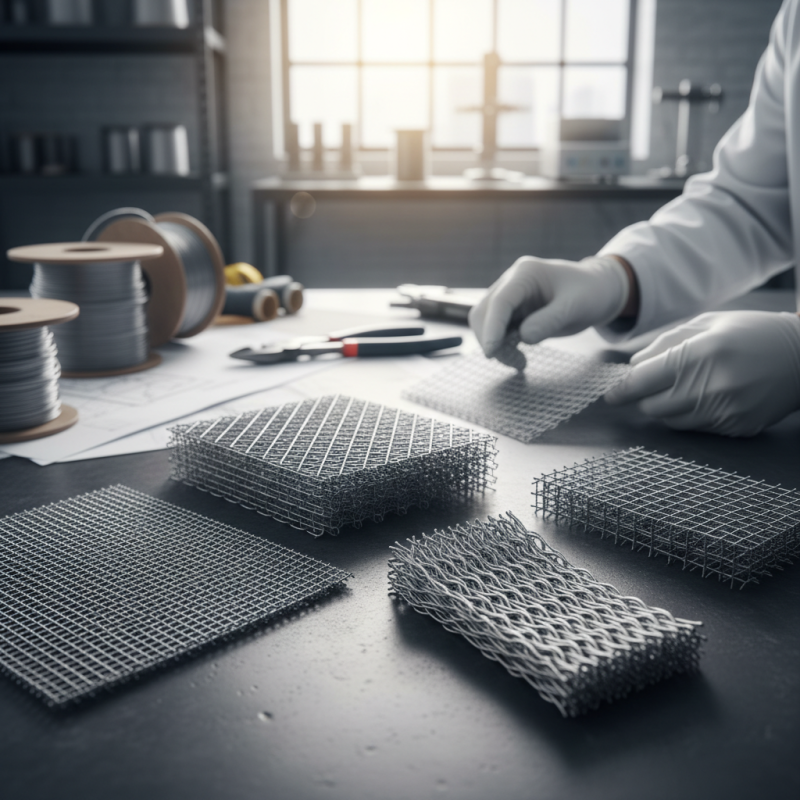

stainless steel wire mesh is used in various applications, from construction to filtration. Each option provides unique benefits. However, understanding these choices can often be overwhelming. Clear specifications, wire diameter, and weave pattern play crucial roles.

Despite the availability of high-quality meshes, not all products are created equal. Some may lack the necessary strength, while others might corrode over time. Engaging with vendors and assessing their offerings becomes critical. One should always ask questions and seek clarity. The pursuit of the best stainless steel wire mesh is indeed a journey requiring diligence and attention to detail.

Understanding Stainless Steel Wire Mesh and Its Applications

Stainless steel wire mesh is widely used across various industries. Its durability and resistance to corrosion make it an ideal choice for many applications. According to a report by Mordor Intelligence, the global stainless steel mesh market is expected to reach $2.9 billion by 2026. This growth reflects the material's adaptability in sectors like construction, food processing, and filtration.

Applications of stainless steel wire mesh vary significantly. In construction, it's used for reinforcement and safety barriers. Its strength ensures structural integrity while resisting harsh environmental conditions. In the food industry, the mesh supports hygiene by preventing contamination. However, some might overlook the importance of proper installation and maintenance. Poorly fitted mesh can lead to failures and safety risks.

In filtration systems, stainless steel mesh offers excellent performance. It effectively traps particles while allowing liquids to pass through. Nevertheless, its effectiveness can diminish over time if not regularly cleaned. The need for routine checks is often underestimated. Awareness of these details can lead to better performance and longer lifespan of the mesh.

2026 Best Stainless Steel Wire Mesh Options to Consider

| Mesh Type | Wire Diameter (mm) | Mesh Opening Size (mm) | Material Grade | Applications |

|---|---|---|---|---|

| Welded Wire Mesh | 1.0 | 25.0 | 304 | Construction, Fencing |

| Expanded Metal | 2.0 | 20.0 | 316 | Architectural, Grating |

| Perforated Sheet | 1.5 | 15.0 | 304 | Filtration, Ventilation |

| Knitted Wire Mesh | 0.8 | 10.0 | 316 | Industrial Filters, Baking Trays |

| Razor Wire Mesh | 1.2 | 30.0 | 304 | Security Fencing, Protection |

Key Factors to Consider When Selecting Stainless Steel Wire Mesh

When choosing stainless steel wire mesh, several key factors should come to the forefront. The mesh’s thickness is crucial; this determines its strength and durability. A thickness of 0.025 inches is often sufficient for light applications. For heavier tasks, consider a mesh around 0.047 inches. Smaller mesh openings can provide better filtration, while larger openings allow for airflow.

Another element to think about is corrosion resistance. Different grades of stainless steel offer varying levels of protection against rust and environmental damage. For example, 304 stainless steel is commonly used but may not be the best for marine environments. Selecting the right grade can be tricky. Costs can increase based on the quality of the material.

Mesh width is also significant. A wider mesh might be more suitable for fencing while finer mesh is ideal for sieving. It’s important not to overlook the intended use. Some applications may require food-grade materials, while others might suffice with industrial-grade options. Every choice has trade-offs, and understanding these can lead to better outcomes.

Top 2026 Stainless Steel Wire Mesh Options for Durability and Safety

When selecting stainless steel wire mesh, durability and safety are crucial factors. Stainless steel offers resistance to corrosion, making it a preferred choice for various applications. For example, in construction, it ensures structural integrity under harsh conditions. Its strength can withstand considerable pressure without bending or breaking. This quality is important for safety, especially in industrial settings.

Consider the mesh size when choosing. A finer mesh provides better filtration but may be less sturdy. Coarser meshes offer greater strength but may not keep small particles out. It’s a balancing act. The finish of the wire is another detail to ponder. Smooth finishes resist wear over time, reducing maintenance needs. However, rougher finishes might be cheaper but can lead to faster deterioration.

In real-world applications, imperfections often arise. Unexpected rust or weld failures can occur, leaving users frustrated. Regular inspections are vital to ensure the mesh remains reliable. Maintenance is sometimes overlooked, yet it significantly impacts longevity and safety. Reflect on how often you check your equipment. Addressing these small but significant oversights can enhance the lifespan of your stainless steel wire mesh.

2026 Best Stainless Steel Wire Mesh Options - Durability Comparison

This chart illustrates the durability values (in MPa) of various stainless steel wire mesh types. Selecting the right mesh type can significantly impact safety and longevity in various applications.

Comparing Different Grades of Stainless Steel Wire Mesh

When selecting stainless steel wire mesh, the grade of the material plays a crucial role in determining its suitability for various applications. Common grades include 304 and 316. The 304 grade is often chosen for its good corrosion resistance and formability. However, it may not be adequate in highly acidic environments. In contrast, 316 grade stainless steel contains molybdenum, which enhances its resistance to chlorides and acids. According to a recent industry report, about 60% of industrial settings prefer 316 for marine applications.

Another factor to consider is wire diameter and mesh size. A finer mesh offers better filtration but may be susceptible to clogging. Conversely, coarser mesh allows for higher flow rates but may not filter out smaller particles effectively. The choice of mesh design often reflects the specific requirements of the industry. Some reports suggest that improper mesh selection can lead to costly maintenance downtime, highlighting the importance of understanding grade differences.

Ultimately, each project's unique challenges should guide the choice of stainless steel wire mesh. Exploring less common grades, such as 2205 duplex stainless steel, may be beneficial for high-stress applications. However, this may complicate sourcing and increase costs. A comprehensive understanding of these grades is critical for effective decision-making.

Installation and Maintenance Tips for Stainless Steel Wire Mesh

When choosing stainless steel wire mesh, installation and maintenance play crucial roles in ensuring longevity and performance. Proper installation methods can significantly impact the efficiency of the mesh. Reports indicate that misalignment during installation leads to a 20% increase in wear and tear.

Here are some tips to consider. Ensure the frame is sturdy. A weak frame can cause sagging over time. Use appropriate fasteners to avoid corrosion. Tighten joints regularly to maintain tension. These small actions have a big impact.

Maintenance is equally important. Corrosion can occur if the mesh isn't cleaned properly. Use non-abrasive cleaners for routine maintenance. A report by the Steel Advancements Institute notes that annual inspections can prevent 30% of potential damages. Pay attention to the environment as well. High humidity areas may require more frequent checks. Addressing these issues promptly can save on costly replacements.