How to Choose the Right Frozen Food Packaging Machine?

Choosing the right frozen food packaging machine is crucial for efficient operations. The global frozen food market is projected to reach $400 billion by 2025. With this growth, packaging plays a vital role. A suitable packaging machine ensures product freshness and compliance with safety standards.

When selecting a packaging machine, consider the type of frozen food you offer. Different products require specific packaging methods. For example, vacuum sealing is essential for preserving flavor and preventing freezer burn. A versatile machine can accommodate various food sizes and shapes, adapting to market trends.

Investing in a high-quality frozen food packaging machine can significantly influence your business success. However, not every machine fits every need. It’s essential to evaluate factors like production speed, material compatibility, and ease of operation. This decision is not trivial; careful consideration can yield substantial cost savings and reduce waste.

Understanding Types of Frozen Food Packaging Machines

Choosing the right frozen food packaging machine is vital for efficiency. Various types are available, each suited for different needs. Some machines focus on vacuum sealing, which removes air and extends shelf life. These are great for perishable items like frozen vegetables and meats.

Others utilize flow wrapping technology. This method wraps products in a continuous film, ideal for bulk items. It's fast and minimizes waste. However, it requires precise adjustments for different product sizes. Some machines offer tray sealing, which is perfect for ready meals. This process creates airtight seals around trays and maintains food quality.

Reflecting on these choices is important. Each type of machine has limitations. For instance, vacuum sealers may struggle with larger products. Flow wrappers could waste materials if not calibrated correctly. Understanding these nuances helps in making the right decision for your frozen food packaging needs.

Types of Frozen Food Packaging Machines

Key Features to Consider in Packaging Machinery

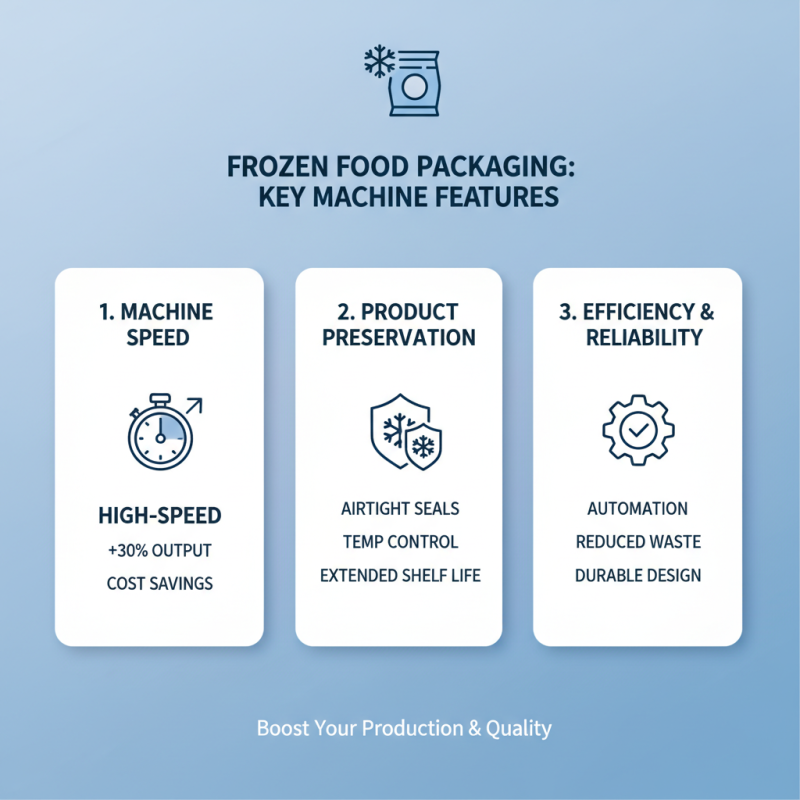

Choosing the right frozen food packaging machine is critical. Several key features enhance efficiency and product preservation. One must consider the machine's speed. According to industry reports, high-speed machines can boost output by up to 30%. This translates to significant cost savings over time.

Seal strength is another vital feature. Weak seals can lead to freezer burn or spoilage. Industry data indicates that a robust seal can increase shelf life by up to 50%. It's essential to test seal integrity regularly.

Tips: Always evaluate the machine's compatibility with different types of packaging materials. Flexibility can save resources and reduce waste.

Consider automation features. Machines equipped with smart technology optimize workflow but may require a higher initial investment. They can cut labor costs significantly.

As you choose, remember that each feature has pros and cons. Analyze your specific needs carefully before making a decision.

Evaluating Production Capacity and Efficiency

When selecting a frozen food packaging machine, production capacity is crucial. A 2022 report indicated that the frozen food market is expected to grow at a compound annual growth rate (CAGR) of 4.5% from 2023 to 2028. This rise demands machinery that can keep pace. Machines should handle various packaging formats, including bags and trays, while maintaining speed.

Efficiency is equally important. The industry's standard efficiency rate is about 80%. However, many operations fall short, with some only achieving 60% capacity. An effective machine should streamline processes, thereby reducing waste and minimizing downtime. Automatic adjustments in packaging speed can increase overall productivity.

Consider the energy consumption of your machinery. Reports show that energy-efficient machines can save up to 30% in operational costs. Yet, many manufacturers overlook this aspect, leading to higher expenses. Investing in quality equipment that balances capacity, efficiency, and cost can yield long-term benefits. Focus on these factors, as they often improve profitability and overall performance.

Assessing the Cost and Budget for Packaging Equipment

When choosing a frozen food packaging machine, budgeting is critical. Assess the total cost of ownership. Initial purchase price matters, but operational costs are equally important. Energy consumption, maintenance, and potential downtime can add up quickly. Make sure to account for these expenses to avoid surprises later.

Consider the machine's efficiency. A low upfront cost might seem appealing. However, less efficient machines can lead to higher ongoing expenses. Look for machines that offer good output rates relative to their price. Research is vital; detailed comparisons can reveal hidden costs.

Don't forget about the future. Will the machine meet your growing needs? Sometimes, a more expensive option can save money in the long run. It’s essential to think about scalability. Budgeting for upgrades can prevent future financial strain. Investing wisely can lead to sustainability.

Maintenance and Support Considerations for Packaging Machines

When choosing a frozen food packaging machine, maintenance is a crucial aspect. Regular upkeep ensures the machine runs smoothly and efficiently. Neglecting maintenance can lead to equipment failure. This may result in production delays and increased costs. Proper care extends the lifespan of your machine.

Tip: Schedule routine checks. Inspect seals and heating elements often. Replace worn parts immediately to avoid bigger issues.

Operator training is also key. Workers should understand how to use the machine correctly. Misuse can lead to damage and waste. They need to know best practices for loading and running the equipment. This training should be ongoing as technology evolves.

Tip: Create a training manual. Use visual aids to help operators learn quickly. This resource can reduce errors and improve safety.

Lastly, consider the availability of support. Reliable manufacturers often provide essential resources. This includes troubleshooting guides and responsive customer service. Evaluate this before making a purchase. Access to support can influence your operation's smoothness significantly.

Tip: Research customer reviews. Look for responses to maintenance inquiries. This feedback can lend insight into the supplier's reliability.

Related Posts

-

How to Choose the Best Frozen Food Packaging Machine for Your Business?

-

Revolutionizing Packaging: The Future of Cartoning Machines in Modern Manufacturing

-

Unlocking Efficiency: Benefits of the Best Cardboard Box Machine for Your Business

-

What is the Best Machine for Food Packaging: A Comprehensive Guide

-

7 Innovative Features of the Best Cartoning Equipment You Should Know About

-

Navigating the 2025 Trends in Best Packaging Equipment for Global Buyers to Enhance Efficiency