How to Choose the Right Food Packaging Equipment for Your Business

Choosing the right food packaging equipment is a crucial decision that can significantly impact your business's efficiency, product integrity, and overall success. With the vast array of options available on the market, businesses face the challenge of selecting equipment that not only meets their current needs but also adapts to future growth and evolving industry standards. This guide aims to simplify the decision-making process by outlining essential considerations in evaluating various types of food packaging equipment. From understanding different packaging materials and technologies to assessing the specific requirements of your product line, this comprehensive approach will help you make informed choices. Ultimately, investing in the appropriate food packaging equipment can enhance your production capabilities, extend shelf life, and improve your brand's reputation in a competitive marketplace.

Identifying Your Business Needs for Food Packaging Equipment

When selecting the right food packaging equipment for your business, it's essential to start by identifying your specific needs. Consider the types of products you intend to package, as different food items require tailored packaging solutions. For example, perishable items such as fresh produce may need vacuum sealing to extend shelf life, while dry products could benefit from heat sealing. Analyzing your product line helps narrow down equipment options that best suit your operational goals.

**Tips:** Evaluate the volume of product you intend to package daily. This will help determine whether you need a machine with high-speed capabilities or a smaller, slower operation. Also, assess the size and shape of your products to find equipment that accommodates them efficiently.

Another critical factor is your budget. High-quality equipment can be a significant investment, so it’s vital to balance durability with cost. Research various manufacturers and look for reviews to ensure you're selecting reliable equipment that minimizes downtime and maximizes productivity.

**Tips:** Consider leasing options if your budget is tight. This can provide access to modern technology without the upfront cost. Additionally, factor in maintenance and support services, as reliable after-sales service can save you time and money in the long run.

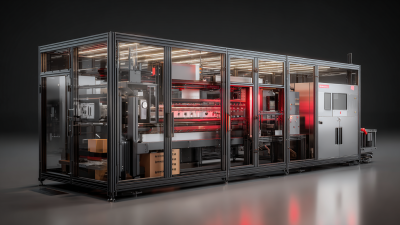

Evaluating Different Types of Packaging Equipment Available

When evaluating different types of packaging equipment available for your food business, it is crucial to consider various factors such as the nature of the products, production speed, and available budget. The packaging machinery market is expected to grow from $46 billion in 2021 to approximately $70 billion by 2032, indicating a robust demand for advanced solutions. Among the types of packaging equipment, vertical form-fill-seal (VFFS) machines are especially popular for their efficiency in packaging granular and powder products, while horizontal form-fill-seal (HFFS) machines are ideal for flexible packaging of items like snacks and ready-to-eat meals.

In addition, the emergence of automation in food packaging cannot be overlooked. According to a report by PMMI, around 67% of packaging operations are now automated, which enhances production efficiency and reduces labor costs. Businesses should also consider specialty equipment, such as vacuum sealers for perishable items or labeling machines that ensure compliance with regulatory standards. Choosing the right equipment will not only streamline your operations but also enhance product shelf life and consumer appeal, ultimately contributing to the bottom line.

Types of Food Packaging Equipment

Analyzing Costs vs. Benefits of Packaging Equipment Options

When selecting food packaging equipment, it's crucial to conduct a comprehensive cost-benefit analysis to ensure alignment with your business goals. Value analysis and value engineering (VAVE) are effective tools that can enhance the performance and efficiency of your packaging operations while optimizing costs. By re-evaluating the design and functionality of packaging equipment, businesses can achieve significant cost improvements without compromising on quality or customer satisfaction. This strategic approach allows companies to weigh the initial investment against long-term savings, leading to more informed purchasing decisions.

Additionally, the interplay between product pricing, packaging design, and consumer behavior cannot be overlooked. Effective packaging not only protects the product but also influences purchasing decisions by conveying value and quality to consumers. As businesses increasingly shift towards sustainable options, such as bioplastics or reusable packaging, understanding these dynamics becomes ever more critical. The evolving landscape of consumer preferences and environmental considerations demands that companies carefully analyze their packaging choices to ensure they meet market demands while controlling production costs.

Understanding Compliance and Safety Standards in Food Packaging

Choosing the right food packaging equipment for your business entails a thorough understanding of compliance and safety standards, which are vital for maintaining consumer confidence. According to the United Kingdom Food Security Report 2021, food safety significantly influences public trust, emphasizing that improper packaging can lead to severe incidents, including foodborne illnesses. With new regulations being implemented, such as the recently approved Packaging and Packaging Waste Regulation, businesses must adapt to mandatory targets for packaging reuse, ensuring that safety measures are not only met but also evolve with consumer expectations.

The importance of compliance is evident as industries face increasing scrutiny regarding packaging materials. Reports indicate that state-specific extended producer responsibility (EPR) programs are emerging, aiming to enforce recyclability and safety standards in food packaging. Innovations in food packaging must align with these requirements while addressing environmental impacts. Research from various institutions suggests that utilizing advanced technologies, such as artificial intelligence, can enhance packaging compliance by minimizing labeling errors and ensuring the utmost safety of food products. Consequently, businesses need to integrate equipment that upholds these standards to not only safeguard their products but also build and maintain consumer trust in the marketplace.

Considering Future Growth and Scalability in Equipment Choices

When selecting food packaging equipment, businesses must consider future growth and scalability alongside current operational needs. With projections indicating that the global data center market will expand at a compound annual growth rate (CAGR) of 26.8%, from $17.73 billion in 2025 to $93.6 billion by 2032, it is evident that industries must prepare for significant increases in demand and technological advancements. This trend echoes the importance of investing in packaging solutions that can adapt to changing market conditions and production requirements.

Moreover, the data center infrastructure market is also anticipated to grow, with estimates showing an increase from $6.69 billion in 2025 to $12.46 billion by 2032, reflecting a CAGR of 9.3%. This growth illustrates the necessity for flexible and scalable equipment tailored to meet future demands. Similarly, food packaging equipment must not only fulfill current packaging standards but also integrate advanced technologies that allow for greater efficiency, sustainability, and adaptability. As the market evolves, businesses need to select machinery capable of supporting innovative packaging solutions that can scale with their growth.

How to Choose the Right Food Packaging Equipment for Your Business - Considering Future Growth and Scalability in Equipment Choices

| Equipment Type | Key Features | Scalability | Estimated Cost ($) | Ideal For |

|---|---|---|---|---|

| Automatic Filling Machine | High speed, precision filling | High scalability for production increase | 15,000 - 50,000 | Mid to large-scale operations |

| Labeling Machine | Auto-labeling, customizable settings | Moderate scalability | 5,000 - 20,000 | Startups to mid-sized businesses |

| Shrink Wrapping Machine | Versatile, energy-efficient | High scalability for various products | 10,000 - 30,000 | Small to large production lines |

| Vacuum Sealer | Prolongs shelf life, easy to use | Great for small batch scaling | 2,000 - 15,000 | Small businesses and culinary startups |

| Cartoning Machine | Fast, reliable cartoning solutions | High scalability for boxed products | 20,000 - 60,000 | Medium to large packaging operations |

Related Posts

-

Leading the World with Quality Chinese Food Packaging Solutions

-

Navigating the 2025 Trends in Best Packaging Equipment for Global Buyers to Enhance Efficiency

-

What is the Best Machine for Food Packaging: A Comprehensive Guide

-

5 Compelling Reasons Your Business Needs the Best Packaging Equipment Today

-

Exploring Innovative Alternatives in Produce Packaging Machinery Solutions

-

5 Essential Tips to Maximize Efficiency with Your Package Machine