How to Choose the Right Chemical Raw Materials Manufacturer?

Choosing the right chemical raw materials manufacturer can be challenging. According to Dr. Emily Carter, a renowned expert in the industry, “Quality and reliability are paramount.” With numerous options available, making an informed decision is essential.

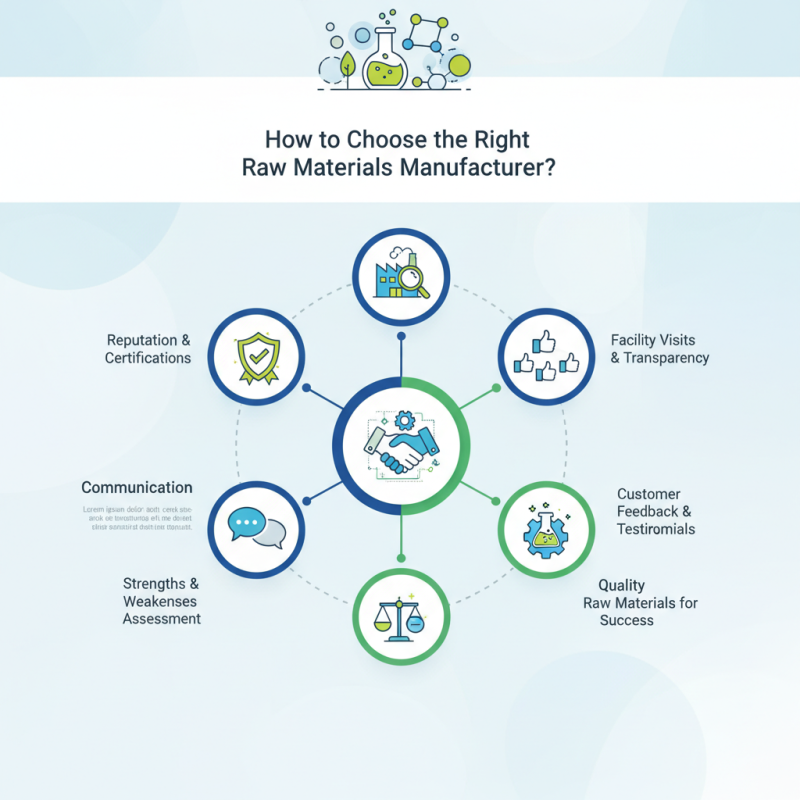

It's important to evaluate manufacturers based on their reputation. Look for certifications that guarantee product quality. Visiting production facilities can provide insights into their operations. A reliable chemical raw materials manufacturer should prioritize transparency and communication. Poor communication often leads to misunderstandings.

Consider customer feedback and testimonials. A manufacturer with many satisfied clients likely values excellence. Nevertheless, remember that no company is perfect. Every manufacturer has areas for improvement. Reflecting on each potential partner’s strengths and weaknesses is vital for making the right choice. Quality raw materials are crucial for your success in manufacturing.

Identifying Your Chemical Raw Material Requirements

Identifying your chemical raw material requirements is crucial for production efficiency. Start by evaluating your product specifications. Understand the properties needed, such as purity levels and physical characteristics. According to a recent industry report, approximately 70% of manufacturers face issues related to quality control. This highlights the importance of knowing what you require.

Additionally, consider the volume of materials needed. A mismatch can lead to shortages or excess stock. Experts suggest that nearly 60% of companies overestimate their raw material needs due to poor forecasting. It’s essential to align your requirements with production schedules. Make adjustments as necessary to avoid wastage.

Communication with suppliers is key. Clearly outline your needs and expectations. Around 50% of manufacturers reported that vague specifications led to supply chain disruptions. Being specific can prevent common misunderstandings. By understanding your precise demands, you can establish partnerships that meet your operational goals better.

Evaluating Manufacturer Certifications and Compliance Standards

When selecting a chemical raw materials manufacturer, certifications and compliance standards are crucial. A manufacturer’s certifications illustrate their commitment to quality and safety. Look for certifications like ISO or REACH. These can indicate adherence to international standards. However, not all certifications are equal. Some may be outdated or not enforced rigorously. Scrutinizing these details can save you from potential risks.

Compliance with local and global regulations also matters. Make sure the manufacturer is compliant with relevant industry regulations. Check for any history of violations. This will provide insight into their reliability. Transparency is key. Ask for documentation and conduct audits if necessary.

Sometimes, manufacturers may show impressive certifications, yet their actual practices might differ. Engage in discussions about their quality control processes. Observe how they handle safety incidents. These factors can reveal their true commitment to compliance. Trust your instincts and be cautious. Even small discrepancies could signify larger issues.

How to Choose the Right Chemical Raw Materials Manufacturer? - Evaluating Manufacturer Certifications and Compliance Standards

| Criteria | Description | Importance Level | Compliance Standards |

|---|---|---|---|

| ISO Certification | Indicates adherence to quality management principles. | High | ISO 9001 |

| Environmental Compliance | Ensures manufacturer follows environmental regulations. | Medium | REACH, RoHS |

| Safety Standards | Compliance with workplace safety practices. | High | OSHA, ANSI |

| Quality Assurance | Processes in place to ensure product quality. | High | ISO 13485 (if applicable) |

| Customer Feedback | Reviews and ratings from previous clients. | Medium | N/A |

Assessing the Quality Control and Assurance Processes

When choosing a chemical raw materials manufacturer, assessing their quality control and assurance processes is crucial. It’s vital to examine their certifications. A reliable manufacturer should hold relevant industry certifications. These certifications indicate their adherence to established quality standards. Additionally, a thorough site visit can offer insight into their operational processes. Observing the manufacturing environment can reveal a lot about their commitment to quality.

Quality control involves rigorous testing and inspection of materials. Ask about their testing methods. Routine checks should be standard practice. Inspect their documentation procedures as well. Consistent records reflect a systematic approach to quality assurance. It’s concerning if records are incomplete or poorly maintained.

Communication is another key aspect. A good manufacturer should welcome questions. Reluctance to share information may suggest inadequate processes. Transparency is essential in building trust. Consider engaging with their existing clients for feedback. Their experiences can provide invaluable insights into the manufacturer's reliability and quality control measures. Remember, choosing a manufacturer is more than just comparing prices.

Quality assurance must be a priority in your decision-making process.

Comparing Pricing Structures and Payment Terms

When choosing a chemical raw materials manufacturer, understanding their pricing structure is crucial. Some manufacturers offer tiered pricing based on order volumes. This can lead to significant savings for larger orders. However, pricing isn't everything. Some may seem cheaper but add hidden costs later.

Payment terms can also vary widely. Some manufacturers require upfront payments, while others may offer credit terms. It's essential to assess what fits your cash flow. A supplier may have a competitive price but inflexible payment terms that strain your budget. Always read the fine print.

Consider the overall value. Sometimes, paying a bit more can lead to better service and quality. Don't rush the selection process. Reflect on your priorities: Is a flexible payment plan more important? Or do you prioritize the lowest initial cost? Making the right choice involves balancing these factors carefully.

Reviewing Customer Feedback and Industry Reputation

When selecting a chemical raw materials manufacturer, customer feedback and industry reputation are crucial. A recent report by the Chemical and Allied Industries Association highlighted that 70% of buyers prioritize reviews before making a decision. Positive feedback can reflect quality and reliability. A consistent pattern of favorable reviews often indicates a trustworthy supplier.

However, not all reviews tell the whole story. Some may be biased or manipulated. It's essential to analyze feedback critically. Look for common themes in customer experiences. Negative comments about delivery times or poor communication can reveal potential red flags. Similarly, a lack of recent reviews might suggest a stagnant performance.

In addition, industry reputation matters. Research from the Global Chemical Industry Conference shows that companies recognized for their ethical practices tend to foster customer loyalty. Recognized manufacturers are often part of industry associations, which can enhance credibility. But remember, reputation isn’t static. Companies can change. Always verify if a manufacturer has experienced recent challenges or controversies. This approach helps ensure a well-informed choice in a complex marketplace.