How to Choose the Right Food Packaging Machine for Your Needs?

Choosing the right food packaging machine is crucial for business success. John Smith, an expert in food packaging technology, once stated, “The right machine enhances efficiency and product quality.” Many factors influence the choice of a food packaging machine. You need to assess your specific requirements carefully.

Consider the type of food you package. Different machines cater to liquids, solids, and semi-solids. Each type presents unique challenges and needs. Understanding these challenges is essential. Your packaging machine must match your production volume. Investing in a machine too large or too small can lead to setbacks.

Quality and durability matter too. You may find cheaper options tempting but often compromise reliability. A machine that frequently breaks down will disrupt your workflow. During your search, keep an eye on customer reviews and expert recommendations. Your choice should align with your vision and goals, yet it may not always feel perfect. Embrace the learning curve involved in selecting the best food packaging machine for your needs.

Understanding Your Food Packaging Needs

Understanding your food packaging needs is crucial for selecting the right machine. A study from the Food Packaging Association found that companies often overlook their specific requirements. Many businesses aim for efficiency, but they forget about customization. Packaging that suits product dimensions and shelf life can save costs significantly.

Consumer preferences have shifted. Research shows that 70% of shoppers prefer sustainable packaging. This trend affects production decisions. Ignoring eco-friendly options may alienate a large customer base. Businesses must assess their values against market demands.

Size and functionality also matter. Reports indicate that 40% of food packaging issues stem from equipment mismatches. A machine that lacks flexibility can lead to wasted materials or time. Keep in mind the future scalability of your production needs. Don't underestimate potential shifts in demand or product lines. Each decision affects the bottom line. Reflecting on these aspects is essential for success.

Types of Food Packaging Machines Available

Selecting the right food packaging machine is crucial for maintaining quality. A proper choice can enhance product shelf life and reduce spoilage. Different types of machines cater to distinct needs in the food industry.

There are several types of food packaging machines available. Vertical form-fill-seal machines are popular for snacks and grains. They are versatile and can handle various bag sizes. On the other hand, tray sealers are perfect for ready-to-eat meals. This machine type provides a tight seal, ensuring the food remains fresh. According to a report by MarketsandMarkets, the food packaging machinery market is expected to grow significantly, driven by advancements in technology.

Another option is filling machines, crucial for liquid products. They ensure precise measurements, reducing waste and improving efficiency. However, some businesses overlook maintenance, leading to breakdowns and delays. Automated solutions offer speed but may require a learning curve for staff. It's essential to weigh these factors against your product needs. Balancing efficiency with quality often presents challenges. Careful consideration of these types can guide you toward the best choice for your operation.

Key Features to Consider in Food Packaging Machines

When selecting a food packaging machine, consider key features that meet your specific needs. One vital element is the machine's capacity. It should align with your production volume. Machines with adjustable settings can help. Look for user-friendly interfaces. Easy operation can save time and reduce errors.

Another important feature is versatility. A machine that can handle different types of packaging materials may be beneficial. Choose one that accommodates both flexible and rigid containers. Ensure the machine is capable of running various sizes as your product line evolves. This adaptability can be a cost-effective choice.

**Tip:** Ask about maintenance and service support. Machines require regular upkeep. An easily serviceable machine reduces downtime. Evaluate the speed and efficiency as well. Sometimes, faster machines can lead to more mistakes. Reflect on your priorities. Is speed or precision more critical for your products? Balancing these aspects is essential for optimal results.

How to Choose the Right Food Packaging Machine for Your Needs

Budgeting for Your Food Packaging Equipment

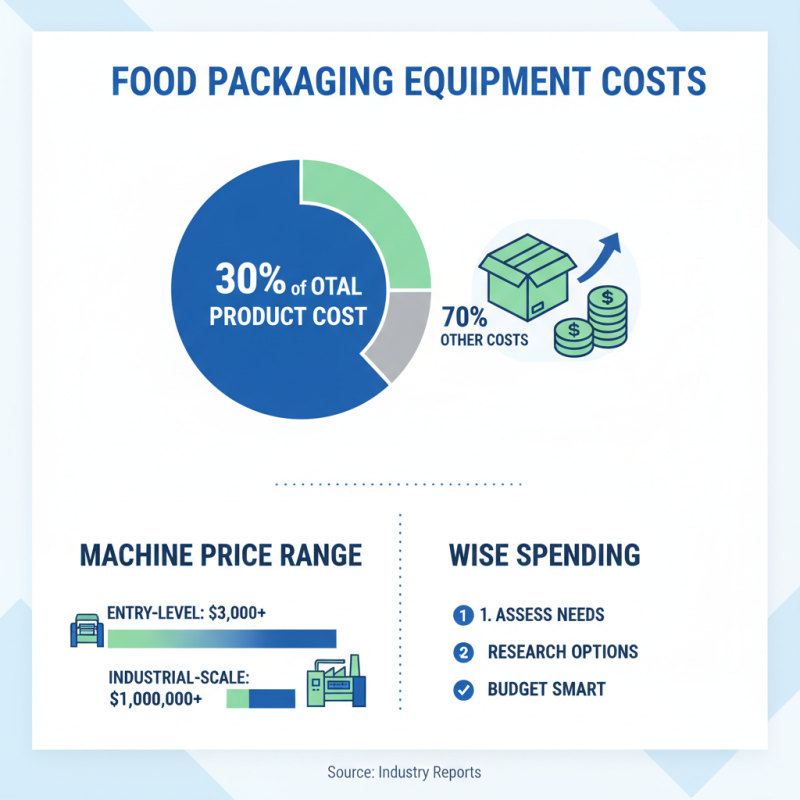

When budgeting for food packaging equipment, understanding costs is crucial. Industry reports indicate that packaging accounts for nearly 30% of total product costs. These numbers highlight the importance of wise spending. Machines vary widely in price, from a few thousand dollars to over a million. It’s essential to assess your specific needs carefully before committing.

Investing in a high-quality machine may offer long-term savings. Cheaper equipment might save you money upfront, but could lead to higher maintenance costs. According to a study by Smithers Pira, packaging machinery improvements can boost production efficiency by 20-30%. This translates into better ROI.

Tip: Consider total cost of ownership. Don’t just look at the purchase price. Factor in maintenance, labor, and downtime costs. Each aspect can add to your overall budget.

Another point to ponder is the technological advancements in packaging. While advanced machines promise efficiency, they often come with a higher price tag. Balance your desire for innovation against your budget constraints. Sometimes, a simpler solution may fit your needs perfectly.

Evaluating Supplier Reputation and Support Services

Choosing the right food packaging machine is crucial for efficiency. Evaluating suppliers is an important step. Industry reports suggest that 70% of companies stress the significance of supplier reputation in their buying decisions. This reflects the need for reliability and quality assurance when selecting equipment.

Supplier support services can affect performance. A study by the Packaging Machinery Manufacturers Institute indicates that 55% of packaging machine failures stem from inadequate support. This underlines the importance of ongoing technical assistance. Look for suppliers who offer regular maintenance and prompt troubleshooting.

Reputation often connects with customer feedback. Engaging with other users can reveal insights. A supplier with a strong track record might score poorly in response times. It’s vital to weigh all factors. Client testimonials can sometimes highlight unexpected issues. Prioritize suppliers who provide transparency and proactive communication.

How to Choose the Right Food Packaging Machine for Your Needs? - Evaluating Supplier Reputation and Support Services

| Criteria | Weights (1-5) | Rating (1-10) | Total Score |

|---|---|---|---|

| Supplier Reputation | 5 | 8 | 40 |

| Customer Support | 4 | 9 | 36 |

| After-sales Service | 4 | 7 | 28 |

| Machine Reliability | 5 | 8 | 40 |

| Technical Support | 3 | 6 | 18 |

| Total Score | 162 | ||

Related Posts

-

How to Choose the Right Food Packaging Equipment for Your Business

-

Leading the World with Quality Chinese Food Packaging Solutions

-

What is the Best Machine for Food Packaging: A Comprehensive Guide

-

Navigating the 2025 Trends in Best Packaging Equipment for Global Buyers to Enhance Efficiency

-

5 Compelling Reasons Your Business Needs the Best Packaging Equipment Today

-

2025 Trends in Technology and How to Choose the Best Equipment Packaging Solutions