How to Choose the Best Stainless Steel Woven Wire Mesh?

Choosing the right stainless steel woven wire mesh can be challenging. Many options exist in the market, each with unique features. The right choice depends on your specific needs and applications.

stainless steel woven wire mesh offers durability and corrosion resistance. It is commonly used in construction, filtration, and automotive industries. Different weaves and wire diameters affect strength and appearance. You may feel overwhelmed by the choices available.

Consider the environment where the mesh will be used. Not all stainless steel woven wire mesh is suitable for every condition. Reflect on your project requirements and seek expert advice when needed. Emphasizing the right qualities makes a difference in performance and longevity. Each decision should align with your project goals.

Types of Stainless Steel Woven Wire Meshes Available in the Market

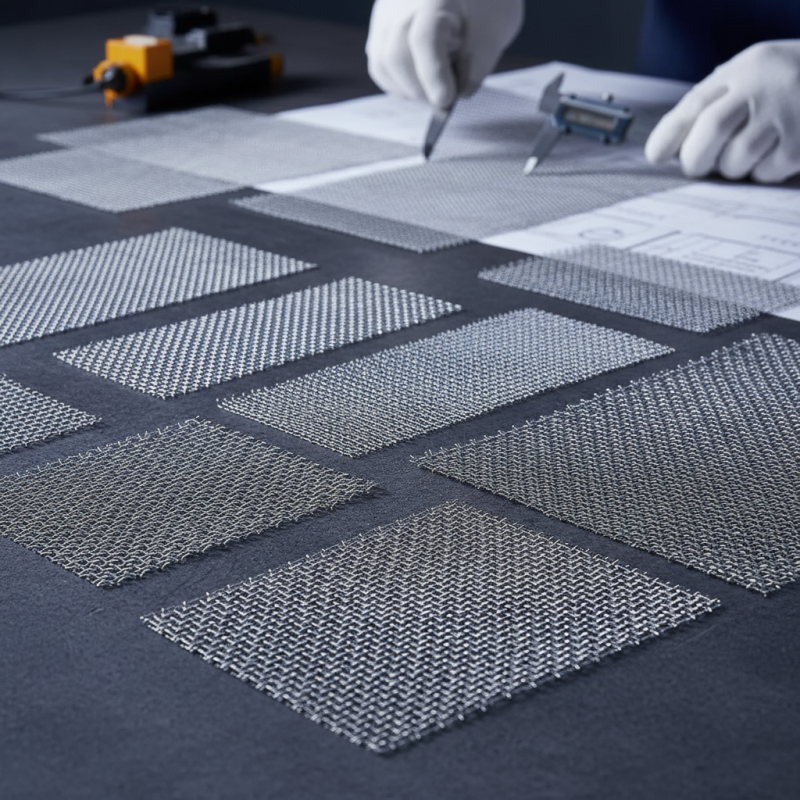

When it comes to stainless steel woven wire meshes, several types are available. Each type caters to specific applications and requirements. The most common varieties include plain weave, twill weave, and Dutch weave.

Plain weave offers balanced tensile strength and openness, making it versatile. Twill weave provides higher strength and a unique texture, ideal for filtering applications. Dutch weave has a thicker wire on one side, making it suitable for finer filtration. The choice depends on your specific needs.

**Tips:** Consider the mesh size and wire diameter. Smaller openings work well for filtration, while larger openings suit separation tasks.

Another aspect is the gauge of the wire itself. A thicker wire means more strength but less flexibility. Test samples whenever possible. This helps in visualizing how they perform under pressure.

Choosing the right type can feel overwhelming. Review your requirements clearly before deciding. Keep in mind, even the best mesh has its limitations. Reflect on these choices as you select the type that will best meet your project needs.

Types of Stainless Steel Woven Wire Meshes in the Market

Key Factors to Consider When Selecting Stainless Steel Woven Wire Mesh

When choosing stainless steel woven wire mesh, several key factors come into play. The specific application is crucial. Industries like food processing or pharmaceuticals require mesh with tight tolerances. According to a report by the International Stainless Steel Forum, nearly 70% of stainless steel production aims to meet such stringent standards. It's essential to identify the right grade of stainless steel. For instance, grades like 304 and 316 offer different levels of corrosion resistance and durability.

Another significant factor is the mesh opening size. This affects both filtration efficiency and airflow. Research indicates that smaller openings can greatly enhance filtering capabilities. However, they might also lead to increased pressure drops in applications. Balancing these needs can be tricky. Additionally, consider the wire diameter, which influences the strength and flexibility of the mesh. A thicker wire may offer more strength but less flexibility, which can complicate installation or maintenance tasks.

Lastly, evaluate the manufacturing process. Different methods affect the consistency and quality of the final product. As a buyer, you want to ensure reliability. Inconsistent mesh can lead to high rejection rates. A study suggested that up to 15% of woven wire products fail quality tests due to this inconsistency. Reflecting on these factors will help in making a more informed decision.

Applications of Stainless Steel Woven Wire Mesh in Various Industries

Stainless steel woven wire mesh is versatile. It finds applications in various industries. The food industry benefits significantly. This mesh serves as filters, ensuring product purity. Cleanliness is vital here, but maintaining it can be challenging. Residue can build up, impacting safety and taste. Regular maintenance is necessary, or contamination risks arise.

In construction, stainless steel wire mesh is critical. It provides stability and strength in concrete applications. This mesh supports structures, but it can rust if not protected. The balance between durability and maintenance is a point of reflection for builders.

The automotive sector uses this mesh, too. It aids in exhaust systems and air filters. The lightweight design improves efficiency. However, improper selection can result in reduced performance. Understanding specific needs becomes essential in this case. Industries depend on woven wire mesh for practical solutions. A little miscalculation in choice can lead to challenges.

Comparing Different Grades of Stainless Steel for Woven Wire Mesh Use

Choosing the right grade of stainless steel is vital for woven wire mesh applications. Different grades offer unique properties. The most common grades are 304 and 316. Both are durable, but they serve different purposes.

Grade 304 is versatile and widely used. It resists corrosion well in many environments. However, it may not perform well in highly acidic conditions. On the other hand, grade 316 includes molybdenum. This addition makes it more resistant to saltwater and chemical exposure. Yet, it can be pricier and less accessible than grade 304.

When selecting woven wire mesh, consider the environment it will face. Avoid assuming one grade fits all scenarios. A thorough assessment is important. Each project may have hidden challenges. Taking the time to understand these needs is essential for optimal performance.

Maintenance and Care Tips for Long-lasting Stainless Steel Woven Wire Mesh

When using stainless steel woven wire mesh, maintenance is essential for longevity. Regular cleaning can prevent rust and buildup. A simple routine with mild soap and water works wonders. Avoid harsh chemicals, as they can damage the mesh.

Here are some tips for keeping your mesh in top shape. Remove debris regularly to avoid corrosion. Inspect for any signs of wear, especially at the joints. If you see any damage, replace the affected section promptly.

Storage is important too. Keep the mesh in a dry area to prevent moisture accumulation. Avoid stacking heavy items on top, which can cause deformities. Proper care and attention can extend the life of your stainless steel woven wire mesh. Remember, maintenance may seem tedious but pays off in the long run.