Transforming Industries: How Flexible Packaging Machines Are Revolutionizing Product Preservation

In the dynamic landscape of modern manufacturing, the emergence of flexible packaging machines has marked a pivotal shift in how products are preserved and presented. According to the Flexible Packaging Association, the flexible packaging market is projected to reach $300 billion by 2025, driven by growing consumer demand for convenience and sustainability. These versatile machines are not merely tools; they are catalysts that enable industries to enhance shelf life, reduce waste, and respond to ever-evolving market demands, leading to significant economic benefits.

As consumers increasingly prioritize freshness and quality, businesses are turning to flexible packaging solutions to meet these expectations. Research from Smithers Pira indicates that 95% of new packaging projects are employing flexible materials due to their ability to reduce transportation costs and minimize carbon footprints. This surge in flexible packaging machines showcases their integral role in not only safeguarding products from spoilage but also in promoting environmentally friendly practices within the industry. In this article, we will explore the top 10 ways flexible packaging machines are revolutionizing product preservation, highlighting their impact across various sectors and underscoring their worth in the contemporary marketplace.

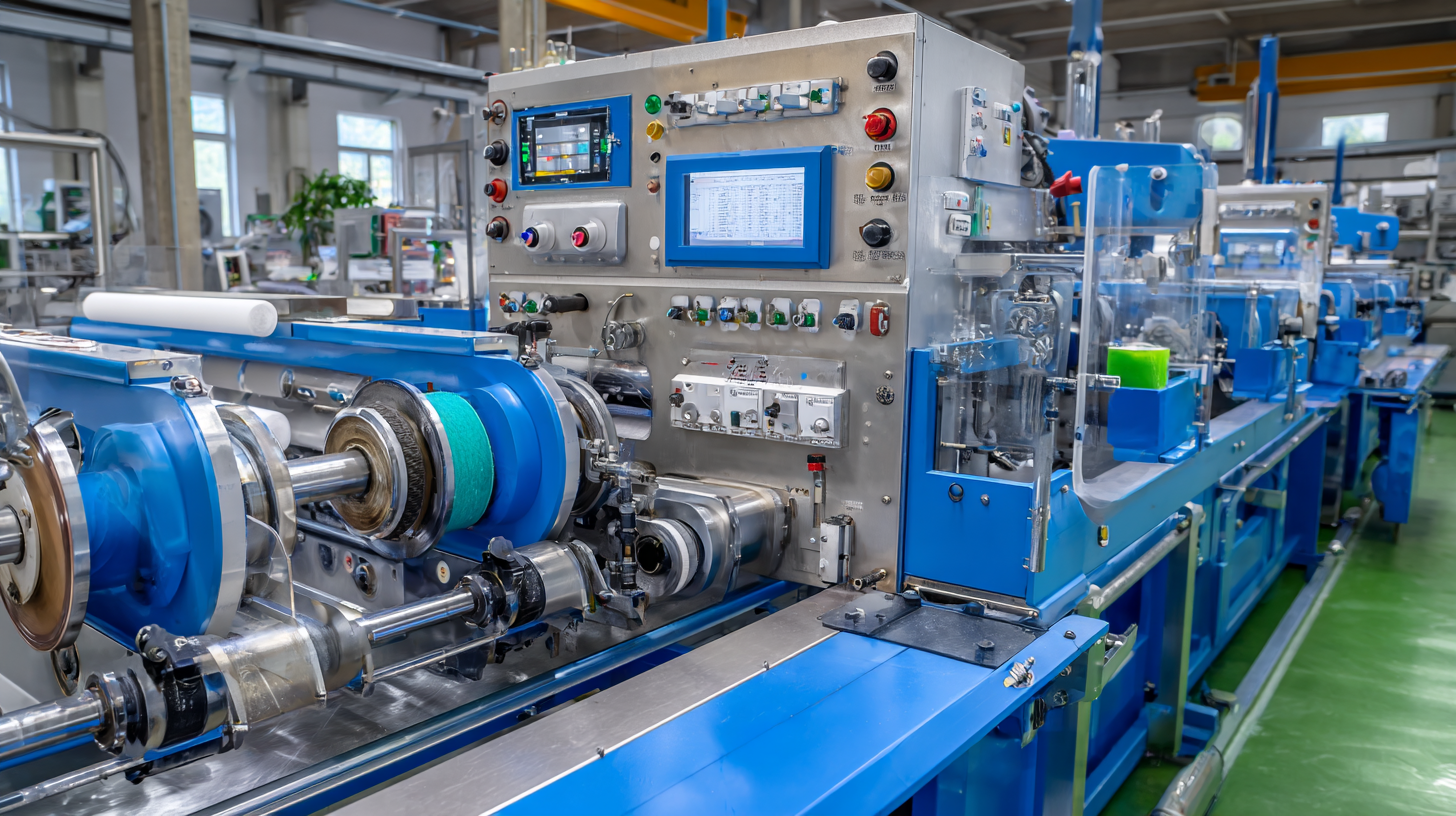

The Evolution of Flexible Packaging Machines in Modern Industries

The evolution of flexible packaging machines has significantly transformed modern industries, particularly in food, pharmaceuticals, and consumer goods. According to a report by MarketsandMarkets, the global flexible packaging market is projected to reach $300 billion by 2025, driven by the demand for convenience and sustainability. This rise of flexible packaging machines allows businesses to enhance product preservation while reducing waste and improving shelf life. Innovative features like vacuum sealing and resealable pouches have become essential in maintaining the freshness and quality of products.

Tips: When considering flexible packaging options, businesses should evaluate the specific needs of their products, such as moisture and oxygen barriers, to choose the most effective solutions. Investing in advanced technology can also lead to increased efficiency and cost savings in production processes.

The technical advancements in flexible packaging machines include automation and integration with digital technology, which have streamlined operations and reduced labor costs. The incorporation of sensors and IoT (Internet of Things) capabilities allows for real-time monitoring and better quality control. A recent study by Smithers Pira found that the adoption of smart packaging solutions could enhance consumer engagement and provide valuable data for companies about their products and market trends.

Tips: To stay competitive, companies should consider not only the functionality of packaging but also the environmental impact, selecting materials that are recyclable or compostable where possible.

Key Benefits of Flexible Packaging for Product Preservation

Flexible packaging has emerged as a game-changer in product preservation, offering numerous advantages that traditional packaging methods cannot match. One of the primary benefits is enhanced shelf life. By creating a barrier against moisture, light, and air, flexible packaging significantly slows down the degradation process of food and other perishable goods. This not only helps maintain quality but also reduces food waste, offering significant environmental benefits and cost savings for businesses.

Tips for utilizing flexible packaging effectively include selecting the right materials tailored to the specific product needs and considering design elements that enhance functionality. Pay attention to sealing methods, as proper seals prevent contamination while extending freshness. Additionally, incorporating resealable options can further improve the user's experience by allowing for easy access and storage.

Another key benefit of flexible packaging lies in its lightweight nature, which aids in reducing transportation costs and carbon emissions. With less weight, companies can ship more products at once, optimizing their logistics. When adopting flexible packaging solutions, consider using biodegradable materials to align with sustainability goals and attract eco-conscious consumers.

Transforming Industries: The Impact of Flexible Packaging on Product Preservation

Technological Innovations Driving the Flexible Packaging Revolution

The flexible packaging industry is experiencing a transformative wave, driven by a series of technological innovations that enhance product preservation. Advanced sealing methods, such as thermoset and cold seal technologies, are ensuring airtight packaging that prolongs shelf life and maintains freshness. This is especially crucial in the food sector, where preventing spoilage and contamination can significantly impact quality and safety. Moreover, smart packaging solutions equipped with sensors are emerging, allowing manufacturers to monitor freshness and provide real-time data to consumers.

Another significant innovation in this field is the adoption of sustainable materials that cater to eco-conscious consumers without compromising on performance. Biodegradable and recyclable films are becoming increasingly popular, enabling companies to reduce their environmental footprint while still offering high-quality preservation. Additionally, improvements in machinery, such as automated production lines and enhanced precision, are reducing waste and increasing efficiency. These advancements not only cater to the growing demand for sustainable practices but also optimize operational costs, signifying a win-win situation for both manufacturers and consumers alike.

Case Studies: Successful Integration of Flexible Packaging Machines

Flexible packaging machines are proving to be game-changers across various industries, with several case studies highlighting their successful integration. One notable example is a leading snack manufacturer that faced challenges with product freshness and shelf life. By adopting a state-of-the-art flexible packaging solution, they were able to extend the freshness of their products significantly. The new system allowed for airtight seals that minimized exposure to moisture and air, effectively keeping the snacks crispy and flavorful for a longer duration. This innovation not only improved customer satisfaction but also reduced product waste, leading to significant cost savings.

Another compelling case study involves a beverage company that sought to enhance its sustainability efforts. They switched to flexible packaging machines that utilized biodegradable materials without compromising on quality. This shift not only aligned with their corporate social responsibility goals but also attracted eco-conscious consumers. The lightweight nature of the flexible packaging reduced transportation costs and carbon footprint, demonstrating that embracing flexible packaging solutions can align environmental goals with business profitability. These case studies exemplify how flexible packaging machines are not just enhancing product preservation but also driving efficiency and sustainability in manufacturing processes.

Future Trends and Challenges in Flexible Packaging Industry

The flexible packaging industry is witnessing significant transformations, driven by innovations that not only enhance product preservation but also meet evolving consumer demands. According to market insights, the flexible packaging market was valued at $27.2 billion in 2022 and is projected to reach $39.4 billion by 2030, reflecting a compound annual growth rate (CAGR) of 5.2% from 2024 to 2030. This growth is largely attributed to advancements in packaging technologies and materials that ensure food quality, safety, and extended shelf life.

As sustainability becomes a focal point, the industry is facing both trends and challenges. The rise of eco-friendly materials and production methods is gaining momentum, with innovations in biodegradable and recyclable options. Additionally, the flexible printing machine market is set to expand substantially, valued at approximately $207.1 million in 2025 and expected to soar to $413.7 million by 2033, indicating a CAGR of 9.03%. The shift towards customized and efficient packaging solutions will be crucial as brands seek to differentiate their products in a competitive landscape while adhering to environmental standards.

Related Posts

-

Exploring Innovative Alternatives in Produce Packaging Machinery Solutions

-

How to Choose the Right Flexible Packaging Machines for Your Business Needs

-

5 Essential Tips to Maximize Efficiency with Your Package Machine

-

Unlocking the Advantages of Bakery Packaging Machines for Global Buyers

-

Ultimate Guide to Efficient Equipment Packaging Solutions for Global Buyers

-

Navigating the 2025 Trends in Best Packaging Equipment for Global Buyers to Enhance Efficiency