The Future of Innovative Flexible Packaging Machines for Sustainable Solutions

As the world increasingly emphasizes sustainability in manufacturing and consumer goods, the role of flexible packaging machines has come to the forefront of innovative solutions. These machines represent a pivotal shift in packaging technology, offering versatility, efficiency, and eco-friendly alternatives to traditional packaging methods.

As the world increasingly emphasizes sustainability in manufacturing and consumer goods, the role of flexible packaging machines has come to the forefront of innovative solutions. These machines represent a pivotal shift in packaging technology, offering versatility, efficiency, and eco-friendly alternatives to traditional packaging methods.

As we look to the future, it is essential to explore how advancements in flexible packaging machines are not only enhancing production capabilities but also aligning with the growing demand for sustainable practices. This blog will delve into the transformative potential of these machines, discussing their innovative designs, materials that minimize environmental impact, and their essential role in creating a more sustainable packaging landscape.

By understanding the future of flexible packaging machines, we can better appreciate their contribution to a greener and more efficient economy.

Identifying Key Features of Innovative Flexible Packaging Machines

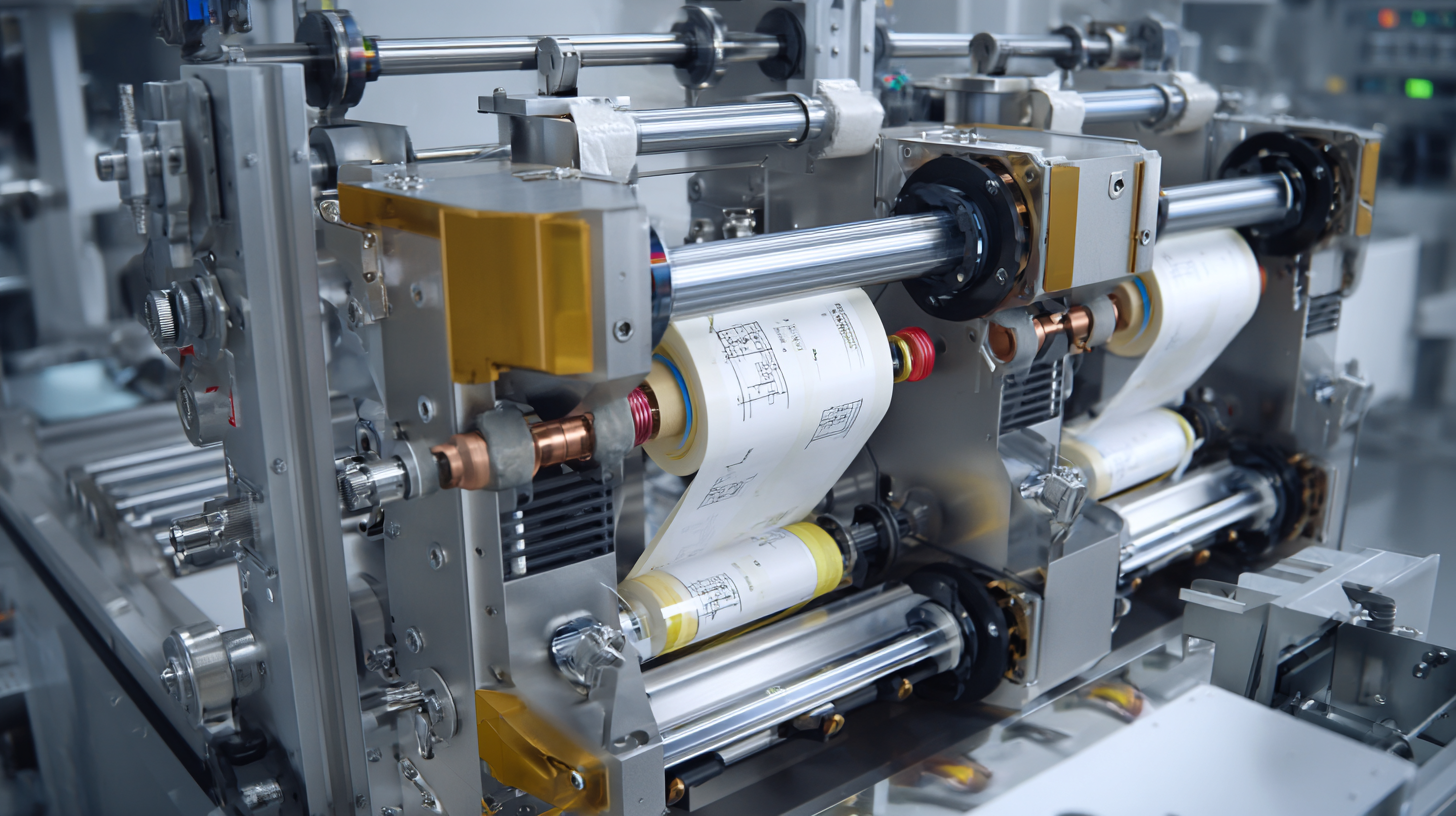

Innovative flexible packaging machines are paving the way for

sustainable solutions in the packaging industry. Key features of these machines focus on enhancing

efficiency while minimizing environmental impact. For instance, advancements in machine learning

are being utilized to optimize packaging processes, ensuring that products are packaged in the most suitable

and recyclable materials. This innovation aligns with the growing demand for eco-friendly packaging that

supports easy recycling and reduces waste.

Innovative flexible packaging machines are paving the way for

sustainable solutions in the packaging industry. Key features of these machines focus on enhancing

efficiency while minimizing environmental impact. For instance, advancements in machine learning

are being utilized to optimize packaging processes, ensuring that products are packaged in the most suitable

and recyclable materials. This innovation aligns with the growing demand for eco-friendly packaging that

supports easy recycling and reduces waste.

Tips for selecting innovative flexible packaging machines include looking for models that offer

versatility in material compatibility and adaptability to various product types. Machines that incorporate

smart technology for real-time monitoring and adjustment can

significantly enhance operational efficiency. Additionally, consider systems that are designed to reduce

the consumption of non-recyclable materials, thus supporting a broader sustainability agenda.

Furthermore, it is crucial to evaluate the footprint of packaging machines regarding energy consumption

and ease of maintenance. Machines that prioritize sustainability not only contribute to corporate responsibility

goals but are also likely to reduce long-term costs associated with packaging and disposal. Emphasizing these

key features will help businesses stay ahead in the evolving landscape of sustainable packaging solutions.

Evaluating Sustainability Standards in Packaging Solutions

As the packaging industry evolves, sustainability has become a pressing concern. Evaluating sustainability standards in packaging solutions is crucial not only for reducing environmental impact but also for meeting consumer demands for eco-friendly products. Companies are now focusing on materials that minimize waste, promote recyclability, and utilize less energy in production. The push towards sustainable packaging is not just a trend; it is becoming a cornerstone of corporate responsibility and brand loyalty.

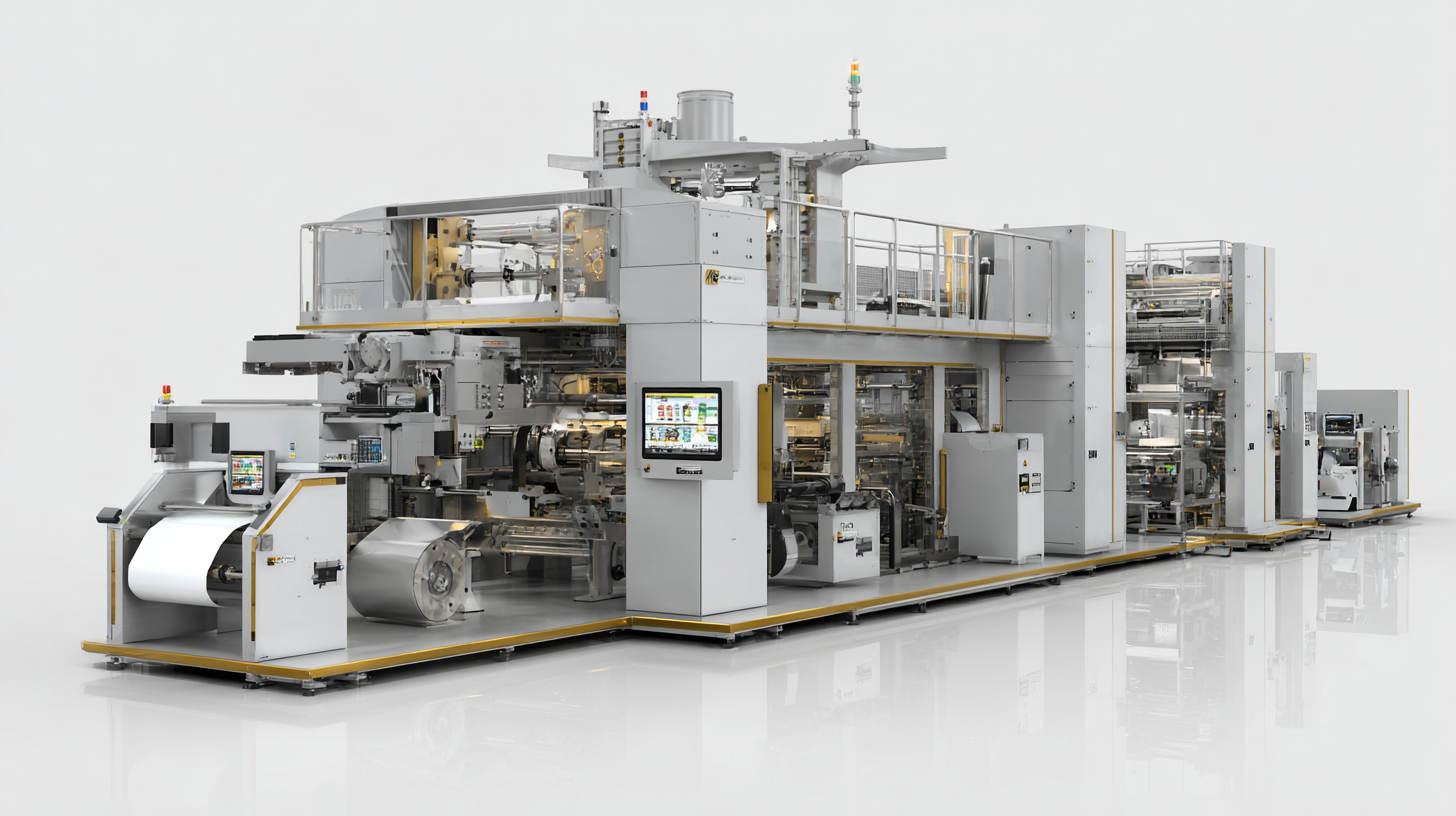

Innovative flexible packaging machines play a vital role in this transformation. By integrating advanced technology, these machines enhance the efficiency of producing sustainable packaging while maintaining product integrity. The development of biodegradable films and recyclable materials is reshaping the packaging landscape, allowing brands to align with sustainability standards effortlessly.

Furthermore, the modular design of contemporary packaging machinery enables businesses to adapt to varying sustainability criteria, ensuring they remain competitive in an increasingly eco-conscious market. With a commitment to evaluating and implementing rigorous sustainability standards, the packaging industry can lead the way toward a more sustainable future.

Creating a Checklist for Selecting Quality Suppliers

When selecting quality suppliers for innovative flexible packaging machines, it is vital to create a comprehensive checklist that prioritizes sustainability and innovation. Start by evaluating the supplier’s commitment to environmentally friendly practices. This includes their use of sustainable materials, energy-efficient manufacturing processes, and the overall lifecycle assessment of their machines. A supplier that invests in green technology not only supports your sustainability goals but also enhances your brand image in an increasingly eco-conscious market.

Next, consider the supplier's track record of innovation. Look for evidence of advanced technology in their machines, such as automation capabilities and adaptability to various packaging needs. Request case studies or testimonials that showcase the supplier's ability to deliver customized solutions that align with your business objectives. Additionally, assess the supplier's customer service and support, ensuring they provide training and assistance for their equipment to maximize your investment. By focusing on these key areas, you can ensure a successful partnership that drives both efficiency and sustainability in your packaging initiatives.

Understanding Market Trends and Future Innovations in Packaging

As the global packaging industry shifts toward sustainability, understanding the market trends and innovations in flexible packaging is crucial. According to a report by Smithers Pira, the flexible packaging market is expected to grow from $215 billion in 2020 to over $300 billion by 2026, driven by increasing consumer demand for eco-friendly solutions. Brands are now prioritizing recyclable materials, leading to a significant rise in the adoption of biodegradable and compostable films. This transition not only meets consumer expectations but also aligns with national and international regulations aimed at reducing plastic waste.

Innovations in flexible packaging machinery play a pivotal role in this evolution. Advanced technologies such as digital printing and automation are enhancing production efficiency while minimizing waste. A study by Mordor Intelligence forecasts that the demand for sustainable packaging machinery will grow at a CAGR of 5.7% from 2021 to 2026. This trend is further propelled by the development of smart packaging solutions, incorporating IoT and sensors to monitor product freshness and optimize supply chains. Such advancements are reshaping the packaging landscape, positioning flexible packaging as a sustainable and innovative option for manufacturers and consumers alike.

The Future of Innovative Flexible Packaging Machines for Sustainable Solutions - Understanding Market Trends and Future Innovations in Packaging

| Dimension | 2023 Market Value (Million USD) | Projected 2028 Market Value (Million USD) | CAGR (2023-2028) | Key Innovations |

|---|---|---|---|---|

| Flexible Packaging Machines | 1,500 | 2,100 | 7.1% | Eco-friendly materials, Automation |

| Biodegradable Packaging Solutions | 800 | 1,500 | 10.5% | Plant-based materials, Reduced carbon footprint |

| Smart Packaging Technologies | 600 | 1,200 | 14.2% | IoT integration, Temperature control |

| Recyclable Flexible Films | 700 | 1,100 | 9.1% | Enhanced recycling processes, Multi-layer films |

Building Long-Term Partnerships with Reliable Packaging Suppliers

Building long-term partnerships with reliable packaging suppliers is essential for the future of innovative flexible packaging machines, especially as sustainability gains traction in the food and beverage industry. According to a recent report by Research and Markets, the global flexible packaging market is projected to reach USD 300 billion by 2024, driven by increasing consumer demand for sustainable solutions and convenience. Aligning with trustworthy suppliers who prioritize eco-friendly materials and sustainable practices can enhance brand reputation and help businesses meet regulatory standards.

Moreover, long-term collaborations with experienced packaging suppliers often lead to significant cost savings and improved product quality. A study by Smithers Pira highlighted that companies engaging in strategic partnerships can experience up to a 20% reduction in packaging waste and a 15% improvement in production efficiency. These partnerships facilitate innovation, allowing businesses to stay ahead of trends while addressing environmental concerns. By fostering mutual trust and open communication, companies can leverage the expertise of reliable suppliers to develop customized packaging solutions tailored to their unique sustainability goals.