2025 Guide: How to Choose the Right Powder Packaging Machine for Your Business

In the dynamic landscape of the packaging industry, selecting the right powder packaging machine is crucial for businesses looking to optimize their operations and enhance product value. As the demand for powdered products continues to rise across various sectors, from food and beverage to pharmaceuticals, understanding the features and functionalities of different packaging machines becomes essential. In this guide, we will explore the vital aspects to consider when choosing a powder packaging machine tailored to your specific needs.

The correct powder packaging machine not only improves efficiency but also ensures the integrity and safety of your products. Factors such as machine capacity, speed, adaptability to different powder types, and ease of use play significant roles in determining the right fit for your business. Additionally, considering the layout of your production line and integration with existing equipment is paramount for seamless operations. This guide aims to equip you with the knowledge necessary to make informed decisions, paving the way for streamlined processes and increased profitability in your packaging endeavors.

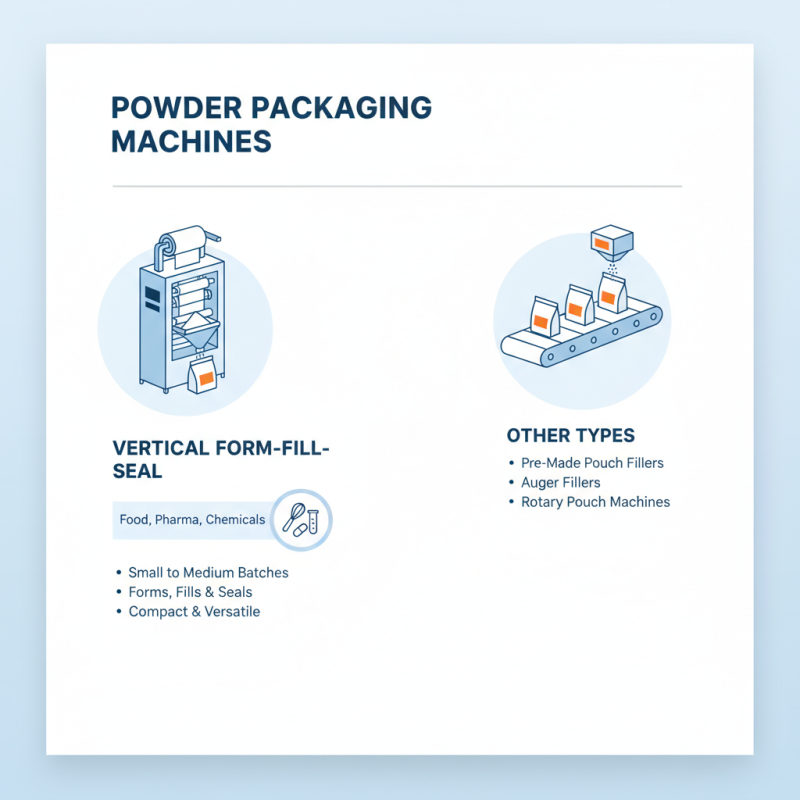

Understanding the Different Types of Powder Packaging Machines

When selecting a powder packaging machine for your business, it's essential to understand the various types available, each designed to cater to specific requirements and operational scales. The most common options include vertical form-fill-seal machines, which are ideal for small to medium-sized batches. These machines operate by forming a pouch from a rolled film, filling it with powder, and sealing it—all in one continuous process. Their compact size and versatility make them suitable for a range of powders, such as food ingredients, pharmaceuticals, and chemicals.

Another type is the auger filler machines, which are particularly effective for precise measurements in packaging applications. They utilize a rotating screw to dispense a specific volume of powder into containers or pouches. This type is favored for its accuracy and is often used in industries where exact weight is crucial, such as in the cosmetics or dietary supplement sectors. Additionally, there are also powder filling machines that operate at higher speeds, catering to high-volume production lines, and can be tailored to accommodate various container sizes.

Each of these machines comes with its unique set of features and capabilities. Evaluating your production needs, such as the volume of powder, required packaging speed, and product characteristics, will guide you in choosing the most suitable machine. Understanding the distinctions among these types will ensure that your investment aligns with your business goals while optimizing efficiency in your packaging operations.

Key Factors to Consider When Choosing a Powder Packaging Machine

When selecting a powder packaging machine for your business, there are several key factors to consider to ensure optimal functionality and efficiency. First, assess the type of powder you will be packaging, as this greatly influences the design of the machine. Different powders, from granulated to very fine, require machines with specific features such as adjustable gates and specialized feeding systems to maintain accuracy and prevent clogging. Additionally, considering the powder's properties can help determine the appropriate packaging materials and techniques.

Another important factor is the machine's capacity and speed. Evaluate your production requirements; this includes how much product you need to package per hour and the size of your operations. A machine that can handle higher throughputs will be essential for meeting demand without compromising on quality. Furthermore, look into the scalability of the machinery. As your business grows, you may need a machine that can adapt or expand its capabilities to accommodate increasing volumes or varying package sizes.

Lastly, the ease of maintenance and operation cannot be overlooked. A user-friendly interface with straightforward controls will reduce the training time for staff and ensure smooth operation. Additionally, consider the availability of support and spare parts for maintenance. A reliable service network can significantly reduce downtime and associated costs, ultimately contributing to your business's efficiency and profitability. By taking these factors into account, you can make an informed decision and select the right powder packaging machine tailored to your business needs.

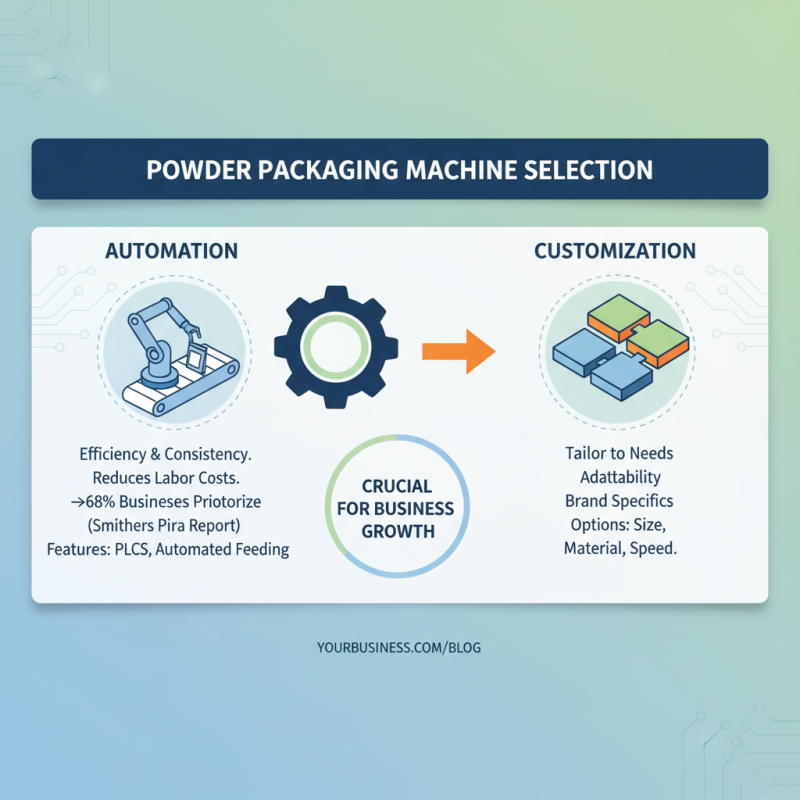

Evaluating Automation and Customization Options for Your Business Needs

When choosing a powder packaging machine for your business, evaluating automation and customization options is crucial. According to a recent report by Smithers Pira, over 68% of businesses in the packaging sector prioritize automation to enhance efficiency and reduce labor costs. Automated machines offer not only speed but also consistency in quality, which is vital for maintaining customer trust. For many operations, integrating sophisticated features such as programmable logic controllers (PLCs) or automated feeding systems can significantly streamline production processes, thereby supporting higher throughput.

Customization options also play an essential role in aligning packaging machines with specific business requirements. A study by Freedonia Group highlights that around 55% of manufacturers are seeking machines that can be tailored for product variability. This need arises from the diverse range of powder products, from food items to pharmaceuticals, each necessitating distinct characteristics in packaging. A machine that can be adjusted for different fill weights, bag sizes, or closure types not only minimizes waste but also enhances flexibility in responding to market changes.

**Tips:** When evaluating machines, consider features such as intuitive software interfaces for easier operation and maintenance. Additionally, prioritize suppliers that offer responsive customer support, as this can significantly impact the overall efficiency of your production line. Remember to assess both initial investment costs and long-term benefits, ensuring that the machine will provide value as your business scales.

Assessing Price vs. Quality: Finding the Best Value in Machinery

When selecting a powder packaging machine, one of the most critical factors to consider is the balance between price and quality. Investing in machinery is a significant commitment for any business, and it is essential to assess how much you are willing to spend against the long-term benefits that quality equipment can provide. Lower-priced machines may seem attractive initially, but they often come with hidden costs such as frequent repairs, lower efficiency, and shorter lifespans. Therefore, it’s crucial to conduct a thorough analysis of the total cost of ownership, which includes maintenance, operational efficiency, and potential downtime.

Quality machinery can lead to improved packaging speeds, reduced waste, and a higher-quality finished product, which can ultimately enhance your business's reputation and profitability. While a higher upfront investment may be necessary, the returns in productivity and reliability can justify the expense. Furthermore, it is important to seek out machines that offer advanced features, such as automation and easy integration into existing production lines. When evaluating suppliers, consider not only the price tag but also the manufacturer’s reputation for quality and support services, ensuring that you achieve the best value for your investment in powder packaging machinery.

2025 Guide: Price vs. Quality in Powder Packaging Machinery

Maintenance and Support: Ensuring Longevity of Your Powder Packaging Machine

When investing in a powder packaging machine, maintenance and support play a critical role in ensuring the longevity and optimal performance of the equipment. Routine maintenance checks, including calibration and cleaning, help prevent unexpected breakdowns and prolong the lifespan of the machine. Establishing a consistent maintenance schedule will reduce the likelihood of costly repairs and downtime, keeping production lines running smoothly.

Tips: To enhance the longevity of your packaging machine, regularly inspect critical components such as seals and conveyors for wear and tear. Keeping a log of maintenance activities can help identify patterns that may indicate underlying issues, allowing for timely intervention.

Additionally, it's vital to select a supplier that offers robust support and easily accessible technical assistance. Training your staff on proper handling and operation of the machine will not only ensure safety but also contribute to its efficiency. Understanding the machine’s specifications, along with any troubleshooting procedures, empowers operators to maintain high productivity levels while minimizing risks of damage or malfunction.

Tips: Consider investing in a preventative maintenance agreement that outlines regular service visits and support, ensuring you have expert assistance when needed.

2025 Guide: How to Choose the Right Powder Packaging Machine for Your Business - Maintenance and Support: Ensuring Longevity of Your Powder Packaging Machine

| Dimension | Description | Frequency of Maintenance | Support Level |

|---|---|---|---|

| Machine Type | Vertical vs Horizontal - Vertical: Best for small to medium businesses - Horizontal: Suitable for larger operations |

Monthly | Technical support, troubleshooting |

| Production Capacity | Output measured in bags per hour - Low Capacity: <= 500 bags/hr - Medium Capacity: 500-1500 bags/hr - High Capacity: > 1500 bags/hr |

Weekly | Full support, training sessions |

| Material Compatibility | Sensitivity to product - Free-flowing powders - Sticky or clumpy powders |

Bi-monthly | Material handling instructions |

| User-Friendliness | Control interface - Touchscreen vs Manual controls |

Quarterly | User manuals, operator training |

| Energy Efficiency | Power consumption - Energy Star rated machines |

Yearly | Energy audits, optimization tips |

Related Posts

-

Unlocking Efficiency: Benefits of the Best Cardboard Box Machine for Your Business

-

Ultimate Guide to Efficient Equipment Packaging Solutions for Global Buyers

-

Unlocking the Advantages of Bakery Packaging Machines for Global Buyers

-

Unmatched Quality from China's Premier Factories Establishing Global Trust in the Best Wrapping Machine

-

Top 10 Cartoning Equipment Solutions for Efficient Packaging Automation

-

How to Optimize Your Production Line with a Doy Pack Machine for Maximum Efficiency