Innovative Liquid Packaging Solutions to Enhance Your Production Efficiency

In today's fast-paced manufacturing environment, optimizing production efficiency is paramount, and innovative liquid packaging solutions play a crucial role in achieving this goal. One of the key advancements in this realm is the development of sophisticated liquid packaging machines that not only streamline the packaging process but also enhance product preservation and presentation. As industries continue to evolve, embracing automation and modern technologies is essential for staying competitive. This guide will delve into various methodologies and strategies to leverage cutting-edge liquid packaging machines effectively, ensuring that your production line operates at its maximum potential. From selecting the right equipment to implementing best practices, this comprehensive overview aims to empower manufacturers with the knowledge needed to enhance their overall operational efficiency through smart liquid packaging solutions.

Identifying the Key Benefits of Innovative Liquid Packaging Solutions

The innovative liquid packaging solutions have become a pivotal element in enhancing production efficiency across various industries. The aseptic packaging market, particularly for pharmaceuticals, is experiencing significant growth. With a value projected at $9.67 billion in 2024 and an anticipated rise to $19.41 billion by 2032, this sector showcases a robust compound annual growth rate (CAGR) of 9.1%. This growth underscores the demand for packaging methods that maintain sterility while also improving operational workflows.

Moreover, sustainable practices in packaging are gaining momentum, with the eco-friendly laundry detergents market expanding rapidly. According to market trends, this sector is shifting towards greener alternatives, contributing to a broader movement for sustainability within the liquid packaging domain. As consumer preferences evolve, businesses are compelled to adopt innovative packaging solutions that not only enhance production efficiency but also align with environmental considerations. Overall, the liquid packaging arena is set to evolve significantly, driven by technological advancements and changing consumer demands.

Choosing the Right Materials for Enhanced Packaging Efficiency

When it comes to innovative liquid packaging solutions, selecting the right materials is crucial for enhancing production efficiency. According to market research, the Nylon 66 market is projected to grow from approximately $451.77 million in 2025 to about $733.18 million by 2033, with a compound annual growth rate (CAGR) of 6.24%. This growth underscores the increasing demand for high-performance materials in packaging applications.

Additionally, cyclic olefin copolymer (COC) is gaining traction in the packaging and medical device sectors. The COC market is expected to see robust application-driven growth, owing to its excellent clarity and barrier properties, which are essential for maintaining product integrity. With the global comprehensive packaging market projected to reach $834.4 billion by 2032, it is evident that the right material choices can significantly contribute to operational efficiency.

Tips:

1. Always assess material properties like transparency and barrier effectiveness to choose the best fit for your packaging needs.

2. Consider engaging suppliers specializing in advanced materials to stay ahead in a rapidly evolving market landscape.

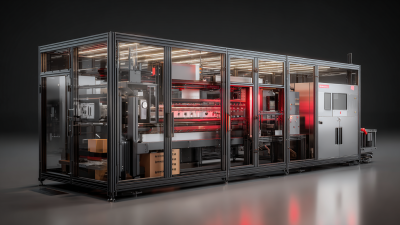

Integrating Technology to Streamline Liquid Packaging Processes

In today's fast-paced manufacturing environment, integrating technology into liquid packaging processes has become essential for enhancing production efficiency. According to a report by Smithers Pira, the global liquid packaging market is projected to reach approximately $410 billion by 2025, with an annual growth rate of 4.3%. This growth underscores the importance of adopting innovative solutions that leverage technology to streamline operations and reduce waste.

Automation and smart packaging technologies, such as IoT-enabled sensors, play a crucial role in optimizing filling lines and improving quality control. These advancements allow manufacturers to monitor production in real-time, leading to minimized downtime and more consistent product quality. For instance, research from Allied Market Research highlights that automated packaging systems can save manufacturers up to 20% on labor costs while enhancing throughput by as much as 30%. By embracing these innovative liquid packaging solutions, companies can not only improve their operational efficiency but also meet the ever-evolving demands of consumers.

Best Practices for Implementing New Packaging Solutions in Production

The adoption of innovative liquid packaging solutions can significantly enhance production efficiency, yet implementing these technologies requires careful consideration of best practices. According to a report by MarketsandMarkets, the global liquid packaging market is projected to reach USD 1 trillion by 2026, indicating a robust growth driven by demand for sustainable packaging options. It is essential for manufacturers to assess their current processes and identify areas where new packaging solutions can be integrated to improve efficiency and reduce waste.

One key practice is to involve cross-functional teams in the evaluation and selection of new packaging technologies. This collaborative approach ensures that all perspectives—from production and quality control to logistics—are considered. A study by McKinsey highlights that companies that leverage team-based approaches to innovation can increase their speed to market by up to 25%. Additionally, pilot testing new packaging solutions can provide valuable insights into their operation, minimizing risks associated with full-scale implementation. Investing in training for staff during this transition is also crucial, as ensuring that employees are well-equipped to handle new systems leads to smoother operations and improved productivity in the long run.

Innovative Liquid Packaging Solutions to Enhance Your Production Efficiency

This chart illustrates the production efficiency gain as a result of implementing innovative liquid packaging solutions. The data reflects the percentage increase in efficiency across different packaging types.

Measuring the Impact of Packaging Innovation on Operational Efficiency

The evolution of liquid packaging solutions has significantly transformed production efficiency across various industries. According to a report by Smithers Pira, innovative packaging solutions can yield operational savings of up to 30% by reducing material waste and enhancing shelf life. By integrating advanced packaging technologies such as smart packaging and reusable containers, companies are not only improving their production processes but also aligning with sustainability goals, which are increasingly important in today's market.

The evolution of liquid packaging solutions has significantly transformed production efficiency across various industries. According to a report by Smithers Pira, innovative packaging solutions can yield operational savings of up to 30% by reducing material waste and enhancing shelf life. By integrating advanced packaging technologies such as smart packaging and reusable containers, companies are not only improving their production processes but also aligning with sustainability goals, which are increasingly important in today's market.

Tips: To enhance your operational efficiency, consider investing in packaging that utilizes less material without compromising structural integrity. Additionally, utilizing vacuum sealing can prolong product shelf life, which results in fewer returns and better inventory management.

Measuring the impact of packaging innovation is equally crucial. A recent study from The Freedonia Group found that well-designed packaging can improve supply chain processes, decreasing shipping costs by up to 10% and minimizing the risk of damage during transportation. Implementing automated packaging systems can also lead to a significant decrease in labor costs, further contributing to operational efficiency. Embracing these innovations not only streamlines production but offers a competitive edge in the marketplace.

Tips: Keep track of performance metrics like shipping times and damage rates post-implementation of new packaging solutions to accurately gauge their effectiveness. Regularly review your packaging strategies to adapt to changing market demands and maintain operational excellence.

Related Posts

-

Navigating the 2025 Trends in Best Packaging Equipment for Global Buyers to Enhance Efficiency

-

How to Choose the Right Flexible Packaging Machines for Your Business Needs

-

How to Optimize Your Food Packaging Process with Advanced Machine Technology

-

Maximizing ROI: How the Best Food Pouch Machine Ensures Low Maintenance Costs and Superior After-Sales Support

-

5 Essential Tips to Maximize Efficiency with Your Package Machine

-

Solutions for Efficient and Reliable Bagging Equipment Selection