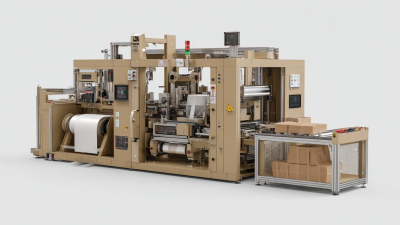

Innovative Solutions for Efficient Bagging Machine Operations

In the competitive landscape of packaging technology, the efficiency of bagging machine operations plays a crucial role in maximizing productivity and reducing operational costs. According to a recent report by MarketsandMarkets, the global bagging machine market is expected to grow from USD 4.1 billion in 2020 to USD 5.6 billion by 2025, reflecting an increasing demand for advanced packing solutions across various industries. This surge emphasizes the need for innovative strategies that enhance the performance of bagging machines. By implementing cutting-edge technologies and optimizing processes, manufacturers can not only improve the accuracy and speed of bagging operations but also minimize waste and downtime. As we delve into the top strategies for efficient bagging machine operations, it becomes clear that embracing innovation is key to staying ahead in this ever-evolving market.

Innovative Technology Driving Bagging Machine Efficiency with Real-Time Data Analytics

The rise of automation and operational efficiency in the manufacturing sector has significantly accelerated the adoption of the Internet of Things (IoT). Innovative technologies enable real-time data analytics, ensuring that bagging machine operations are streamlined and efficient. These advancements are integral for the agricultural industry, particularly in grain processing, where sophisticated machinery transforms raw products into refined staples like flour and rice. At recent trade conferences, smart milling machines and AI sorting technology showcased how these innovations are driving the modernization of essential agricultural equipment.

As industries embrace Industry 4.0, the integration of IoT, artificial intelligence, and cloud computing technologies has become pivotal for enhancing manufacturing efficiency. The growing penetration of these technologies allows for advanced analytics, providing manufacturers with insightful data that informs operational decisions. This not only optimizes productivity but also fosters supply chain transparency and traceability, vital for keeping pace in today's competitive market. As the demand for intelligent packaging solutions rises, we can expect significant growth in the AI packaging market, further reinforcing the trend towards smarter manufacturing processes.

Efficiency Comparison of Bagging Machines with Real-Time Data Analytics

This chart demonstrates the efficiency of various bagging machines before and after the implementation of real-time data analytics technology. The metrics include speed (bags per minute) and accuracy (percentage of correct fills) to highlight the improvements achieved through innovative solutions.

Optimizing Production Line Performance: The Role of AI in Bagging Solutions

The role of AI in optimizing production line performance, particularly in bagging solutions, cannot be overstated. As the global packaging automation market is projected to grow from $78.27 billion in 2025 to $134.65 billion by 2032—reflecting an impressive CAGR of 8.06%—manufacturers are increasingly turning to innovative technologies. Implementing AI in bagging operations streamlines processes, enhances precision, and significantly boosts overall efficiency.

With AI-driven solutions, companies can monitor performance metrics in real time, enabling them to make data-informed adjustments that minimize waste and downtime. For instance, predictive analytics can forecast potential equipment failures, allowing for proactive maintenance and fewer disruptions on the production line. Additionally, machine learning algorithms can optimize packing patterns and configurations, ensuring that products are bagged in the most efficient manner possible, leading to increased throughput and reduced operational costs.

The integration of such innovative technologies is crucial for staying competitive in the rapidly evolving packaging landscape. As the demand for automated packaging solutions continues to rise, businesses that leverage AI for their bagging operations will not only enhance productivity but also position themselves as leaders in the industry.

Reducing Downtime: Predictive Maintenance Strategies for Bagging Machines

In the fast-paced world of manufacturing, reducing downtime is crucial for maintaining productivity, especially for bagging machines that play a pivotal role in packaging processes. Predictive maintenance strategies have emerged as a game-changer for facility managers, allowing them to anticipate machine failures before they occur. According to a report by the McKinsey Global Institute, predictive maintenance can reduce maintenance costs by up to 30% and decrease unplanned downtime by as much as 50%, ensuring operational efficiency.

In the fast-paced world of manufacturing, reducing downtime is crucial for maintaining productivity, especially for bagging machines that play a pivotal role in packaging processes. Predictive maintenance strategies have emerged as a game-changer for facility managers, allowing them to anticipate machine failures before they occur. According to a report by the McKinsey Global Institute, predictive maintenance can reduce maintenance costs by up to 30% and decrease unplanned downtime by as much as 50%, ensuring operational efficiency.

A solid predictive maintenance strategy typically involves the integration of IoT sensors and advanced analytics. These tools monitor various machine parameters, collecting data in real-time to identify potential issues. For instance, vibration analysis can detect imbalances in the motors or bearings, while thermal imaging can identify overheated components. Implementing these technologies can lead to significant savings and increased machine lifespan.

Tip: Regularly train your staff on data analysis tools to better understand maintenance notifications. This proactive approach not only enhances their skill set but also empowers them to act swiftly on maintenance alerts.

Another effective strategy includes establishing a scheduled maintenance plan based on predictive data insights. By timing routine checks when the risk of failure is low, manufacturers can minimize disruption. The U.S. Department of Energy states that organizations that adopt such practices can enjoy up to a 25% increase in productivity.

Tip: Consider a cross-departmental team to review maintenance data weekly, ensuring all departments are aligned and informed about machine statuses and upcoming maintenance schedules. This can lead to a more cohesive operational workflow.

Sustainable Practices in Bagging Operations: Metrics and Industry Standards

The adoption of sustainable practices in bagging machine operations is becoming increasingly essential as industries embrace eco-friendly initiatives. Key metrics such as energy consumption, waste reduction, and material sustainability not only enhance operational efficiency but also contribute to a greener planet. By monitoring these metrics, companies can identify areas for improvement, leading to a more responsible approach in their bagging processes.

For instance, optimizing machine settings can minimize energy usage, while careful selection of biodegradable materials can significantly reduce environmental impact.

For instance, optimizing machine settings can minimize energy usage, while careful selection of biodegradable materials can significantly reduce environmental impact.

Moreover, industry standards play a crucial role in guiding sustainable practices. Organizations are encouraged to adhere to established benchmarks that promote efficiency and sustainability. Compliance with certifications like ISO 14001 can streamline processes and ensure that companies are aligned with global sustainability goals. Implementing training for staff on these standards fosters a culture of sustainability within the workforce. By innovating and adopting best practices in bagging operations, businesses not only improve their performance but also contribute positively to their communities and the environment.

Enhancing Operator Training with Digital Tools for Superior Bagging Outcomes

In today's fast-paced manufacturing environment, enhancing operator training has become essential for achieving superior performance in bagging machine operations. Digital tools have emerged as a transformative solution, facilitating a more interactive and engaging learning experience. Through the use of virtual reality (VR) simulations, operators can practice their skills in a risk-free setting, allowing them to familiarize themselves with complex machinery and procedures. This hands-on approach not only boosts confidence but also reduces the learning curve, leading to more efficient operations on the production floor.

Furthermore, incorporating data analytics into training programs offers unprecedented insights into operator performance. By tracking metrics such as speed and accuracy, trainers can identify areas for improvement and customize the training modules accordingly. This tailored approach ensures that each operator receives the support they need to excel, ultimately enhancing the effectiveness of machine operations. As the industry continues to evolve, leveraging digital tools for training is not just an option; it is a vital strategy for optimizing bagging outcomes and maintaining a competitive edge.

Innovative Solutions for Efficient Bagging Machine Operations - Enhancing Operator Training with Digital Tools for Superior Bagging Outcomes

| Operator Name | Training Program | Digital Tool Used | Efficiency Improvement (%) | Training Completion Date |

|---|---|---|---|---|

| John Doe | Basic Bagging Techniques | Virtual Simulation | 20 | 2023-01-15 |

| Jane Smith | Advanced Bagging Techniques | Interactive Learning App | 25 | 2023-02-20 |

| Mike Johnson | Safety and Compliance | Augmented Reality | 30 | 2023-03-10 |

| Emily Davis | Troubleshooting Bagging Machines | E-Learning Module | 15 | 2023-04-05 |

Related Posts

-

7 Reasons Why the Best Bagging Machine Will Transform Your Packaging Process

-

Unlocking Efficiency: Exploring the Versatile Applications and Benefits of the Best Package Machines in Global Industries

-

Key Factors to Identify Quality Manufacturers for the Best Bagging Machines

-

What is the Best Machine for Food Packaging: A Comprehensive Guide

-

Global Reach of Chinese Manufacturing in Best Packaging Equipment with Trusted Quality Standards

-

How to Choose the Best Cardboard Box Machine for Your Packaging Needs: Insights & Trends