5 Essential Tips to Maximize Efficiency with Your Package Machine

In the fast-paced world of manufacturing and packaging, maximizing efficiency with your package machine is crucial for maintaining competitiveness and profitability. As industries evolve, the demand for streamlined processes and reduced operational costs intensifies, making it essential to harness the full potential of your packaging equipment. This blog aims to provide you with five essential tips that will help you enhance the performance of your package machine. By implementing these strategies, you can not only improve output but also ensure the consistent quality of your packaged products. Whether you're a seasoned professional or new to the packaging industry, these insights will equip you with the knowledge needed to optimize your machinery and ultimately elevate your business operations.

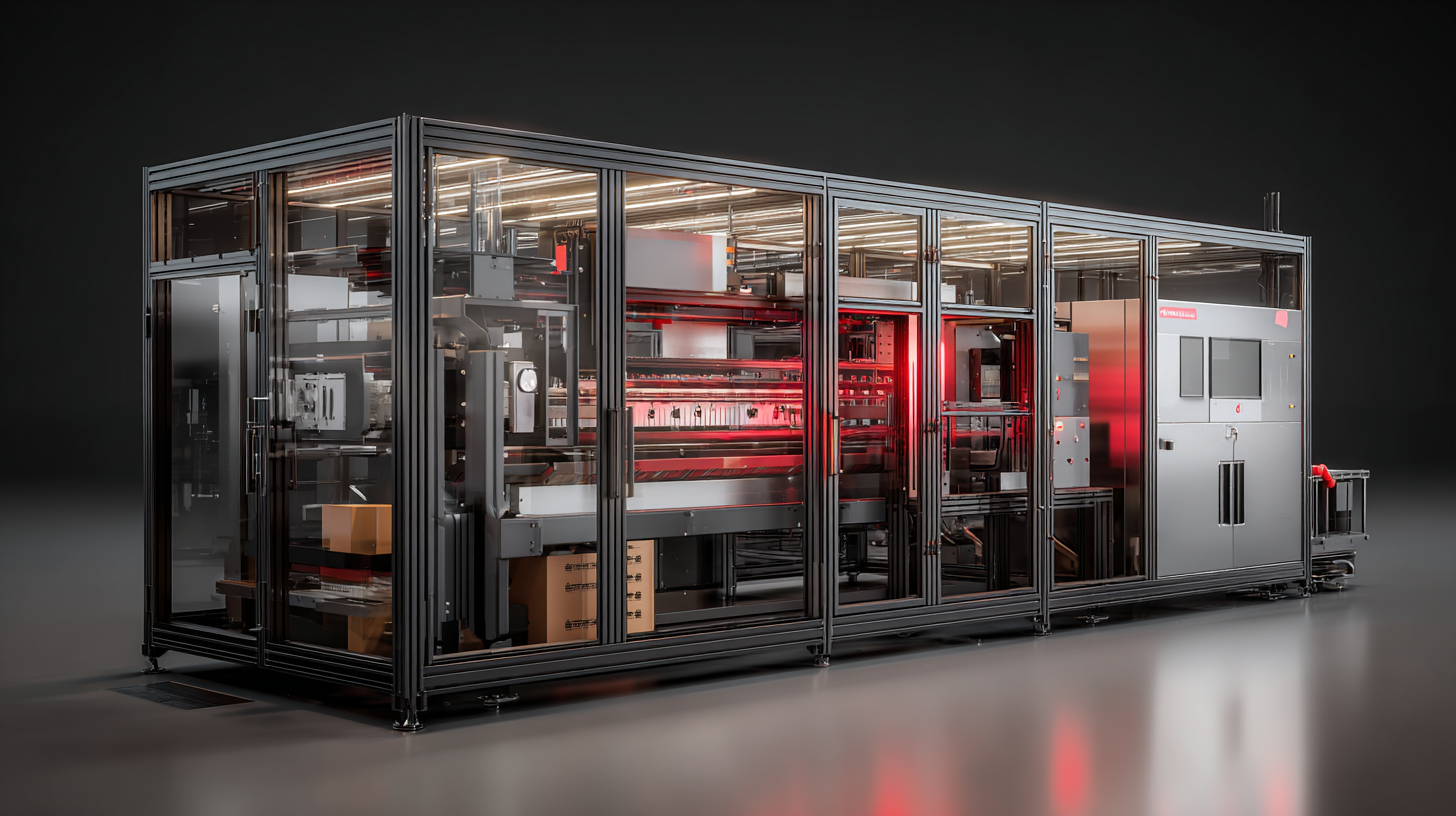

Understanding Your Package Machine: A User's Guide to Efficiency

Understanding your package machine is crucial for maximizing efficiency in any production environment. To start, familiarize yourself with the machine's components and their functionalities. Each part plays a vital role in the packaging process, and knowing how they operate can help you quickly identify issues that may arise. Take the time to read the user manual thoroughly; it often provides insights into maintenance schedules and troubleshooting tips. This foundational knowledge will empower you to make informed decisions and adjustments while operating the machine.

Additionally, periodic training sessions for all personnel involved in the packaging process can enhance operational efficiency. Regularly updating staff on best practices and new features of the machine ensures everyone is equipped to handle the equipment effectively. Encourage an environment where team members can share insights or experiences that could benefit others. By collectively understanding the machine and its processes, you create a more competent and responsive team capable of optimizing productivity and reducing downtime.

5 Essential Tips to Maximize Efficiency with Your Package Machine

This chart illustrates the impact of different factors on the efficiency of package machines. The data represents the average efficiency percentage observed when applying specific tips to improve performance.

Regular Maintenance: Keeping Your Machine in Top Working Condition

Regular maintenance is crucial in ensuring that your package machine operates optimally, reducing downtime and increasing productivity. According to a report by the Packaging Machinery Manufacturers Institute (PMMI), regular machine maintenance can prevent up to 30% of unexpected failures. This statistic highlights the importance of implementing a robust maintenance schedule to avoid costly interruptions in production.

Scheduled maintenance not only extends the lifespan of your packaging equipment but also improves efficiency. ASI (Applied Statistics International) found that businesses investing in preventive maintenance experience a 12% increase in operational efficiency compared to those who do not prioritize upkeep. This translates to more consistent output and a reduction in the likelihood of delays due to equipment malfunction. By addressing minor issues before they escalate, companies save significant resources over time, allowing them to operate with a more streamlined approach.

Optimizing Workflow: Strategies to Enhance Package Machine Performance

In today’s fast-paced production environment, optimizing workflow is crucial for enhancing package machine performance. One effective strategy is to conduct regular maintenance checks. Ensuring all components are in peak condition prevents breakdowns and reduces downtime. Schedule routine inspections and replace any worn parts promptly to keep your operations running smoothly.

Another key aspect to consider is the setup of the workspace. An organized and efficient layout can significantly boost productivity. Arrange materials and tools within easy reach of your package machine to minimize unnecessary movement. Implementing lean principles can also streamline processes. Reduce clutter and establish clear pathways to enhance workflow efficiency.

Training operators effectively is essential for maximizing the machine's capabilities. Ensure that all personnel are well-versed in operating procedures and troubleshooting common issues. Regular training sessions can empower your team, leading to faster problem resolution and optimized machine performance. By implementing these strategies, you can enhance your package machine's efficiency and drive productivity in your operations.

Training Staff: Empowering Your Team for Maximum Efficiency

Training your staff is a crucial element in ensuring that your packaging machine operates at peak efficiency. Empowering your team with the right skills and knowledge can significantly reduce downtime and enhance productivity. Begin by implementing comprehensive training sessions that cover not only the technical aspects of the machinery but also best practices for packaging processes. This holistic approach ensures that your team is familiar with both the equipment and the workflow, leading to greater confidence and performance on the job.

Furthermore, fostering an environment of ongoing learning is essential. Encourage staff to participate in workshops and industry seminars to stay updated on the latest technology and techniques in packaging. This can also include cross-training opportunities, where employees can learn different roles within the packaging process. By promoting a culture of continuous improvement, your team will feel valued and motivated to contribute their best efforts, ultimately driving the efficiency of your packaging operations to new heights.

Leveraging Technology: Smart Solutions to Improve Packaging Processes

In today's fast-paced manufacturing environment, leveraging technology in packaging processes can lead to significant efficiency gains. Implementing smart solutions, such as automated packaging systems and real-time monitoring tools, enables businesses to streamline operations and reduce downtime. By integrating these technologies, operators can gain valuable insights into machine performance and optimize workflows, leading to faster turnaround times and enhanced output.

Further enhancing packaging efficiency, the adoption of IoT devices allows for remote monitoring and predictive maintenance. This means potential issues can be identified and addressed before they cause disruptions, minimizing costly delays. Additionally, smart packaging solutions, such as RFID tags and QR codes, not only improve inventory management but also enhance traceability and customer engagement. Ultimately, embracing these technological advancements empowers businesses to stay competitive while refining their packaging processes for maximum efficiency.

5 Essential Tips to Maximize Efficiency with Your Package Machine - Leveraging Technology: Smart Solutions to Improve Packaging Processes

| Tip Number | Tip Description | Expected Impact (%) | Implementation Time (Hours) |

|---|---|---|---|

| 1 | Utilize automation software for real-time monitoring | 20% | 10 |

| 2 | Implement smart sensors for predictive maintenance | 25% | 12 |

| 3 | Adopt modular packaging systems for flexibility | 15% | 8 |

| 4 | Integrate RFID technology for inventory management | 30% | 15 |

| 5 | Train staff on machine optimization techniques | 10% | 5 |

Related Posts

-

Navigating the 2025 Trends in Best Packaging Equipment for Global Buyers to Enhance Efficiency

-

Unmatched Quality from Trusted Chinese Manufacturers for the Best Package Equipment

-

5 Compelling Reasons Your Business Needs the Best Packaging Equipment Today

-

Unlocking Efficiency: Exploring the Versatile Applications and Benefits of the Best Package Machines in Global Industries

-

Unmatched Quality from China's Premier Factories Establishing Global Trust in the Best Wrapping Machine

-

Leading the World with Quality Chinese Food Packaging Solutions