How to Optimize Your Production Line with a Doy Pack Machine for Maximum Efficiency

In today's highly competitive manufacturing landscape, optimizing production lines is essential for maintaining efficiency and reducing costs. One of the most effective ways to achieve this is through the integration of advanced packaging technology, specifically the doy pack machine. According to a report by Smithers Pira, the flexible packaging market is projected to reach approximately $300 billion by 2024, highlighting the growing importance of innovative packaging solutions.

The doy pack machine not only enhances productivity by accommodating various packaging formats but also significantly reduces material waste. This is especially crucial as industry statistics indicate that minimized waste can lead to up to a 30% reduction in operational costs. By adopting a doy pack machine, manufacturers can streamline processes, enhance product appeal, and ultimately drive higher profit margins.

Understanding the Basics of Doy Pack Machines and Their Benefits

Doy pack machines are specialized packaging systems designed to create highly efficient and visually appealing stand-up pouches, which are widely used in the food, beverage, and consumer goods industries. These machines are capable of producing durable pouches that not only enhance shelf life but also attract customers with their convenience and modern design. Understanding the basic workings of a Doy pack machine is essential for any manufacturer looking to streamline their production process. Typically, these machines operate by forming, filling, and sealing pouches in a single continuous line, significantly reducing labor costs and potential errors compared to traditional packaging methods.

Doy pack machines are specialized packaging systems designed to create highly efficient and visually appealing stand-up pouches, which are widely used in the food, beverage, and consumer goods industries. These machines are capable of producing durable pouches that not only enhance shelf life but also attract customers with their convenience and modern design. Understanding the basic workings of a Doy pack machine is essential for any manufacturer looking to streamline their production process. Typically, these machines operate by forming, filling, and sealing pouches in a single continuous line, significantly reducing labor costs and potential errors compared to traditional packaging methods.

The benefits of utilizing Doy pack machines are numerous. First, they offer versatility in packaging a variety of products, from liquids to solids, making them ideal for different industries. Moreover, the use of stand-up pouches minimizes storage space and shipping costs due to their lightweight nature and efficient design. These machines also allow for customization in size, shape, and printing, which helps brands stand out in a competitive market. By adopting a Doy pack machine, companies can not only enhance their operational efficiency but also improve product presentation, thus driving sales and customer satisfaction.

Key Features to Look for When Selecting a Doy Pack Machine

When selecting a Doy Pack machine to optimize your production line, there are several key features to consider. First and foremost, the machine's speed and efficiency are crucial. Look for machines that offer adjustable speeds to adapt to your production needs. This flexibility ensures you can scale up for large batches or slow down for more intricate packaging requirements, ultimately maximizing your output.

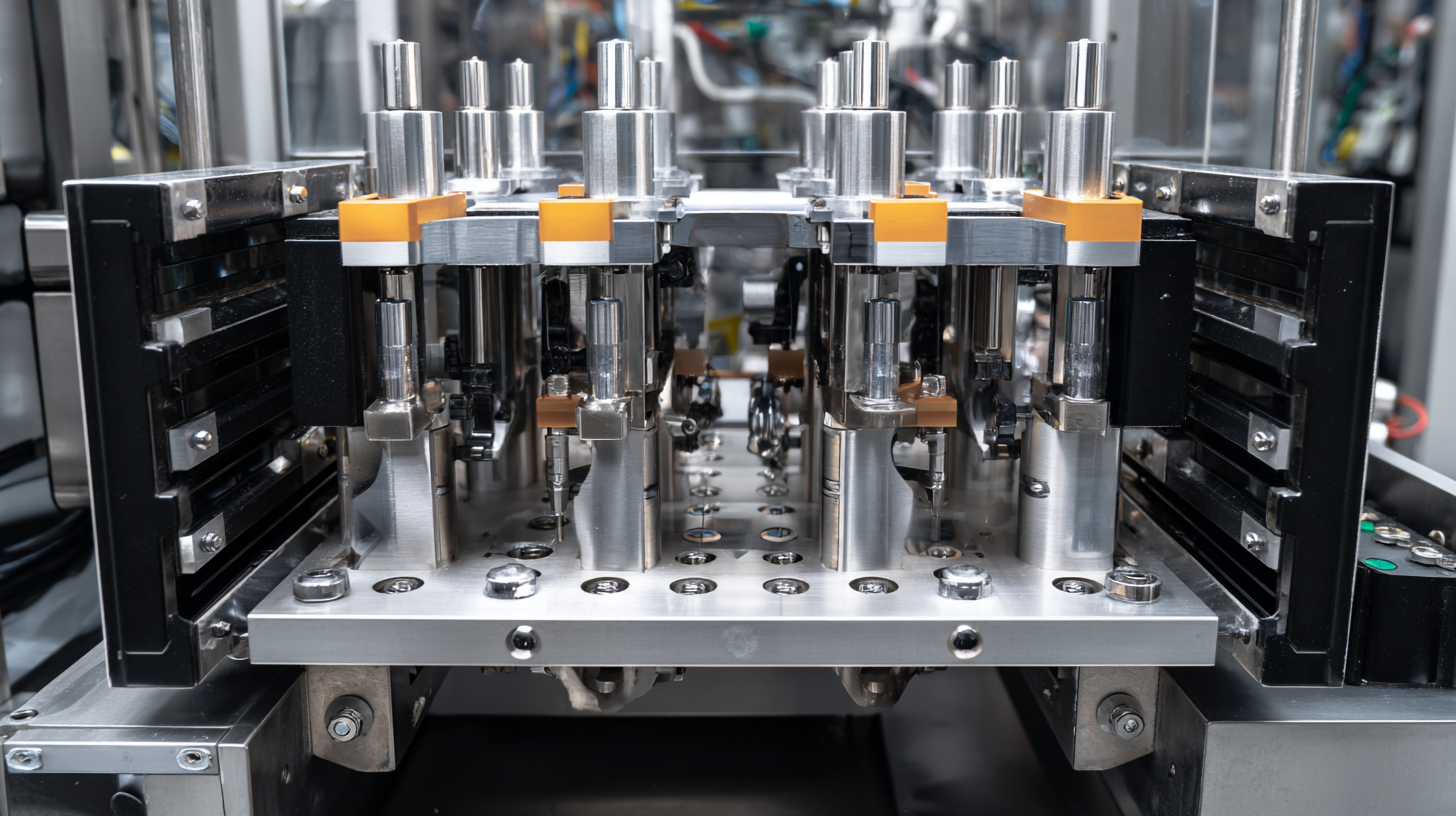

Another critical feature is the machine's versatility. An ideal Doy Pack machine should handle a variety of product types and pouch sizes without extensive manual adjustments. This adaptability not only saves time but also reduces downtime during changeovers, allowing for a smoother workflow. Moreover, consider machines that come with integrated technologies such as automatic filling systems and quality control sensors, which enhance precision and reduce wastage.

Tips for optimizing your Doy Pack machine selection include evaluating the machine's ease of maintenance. Regular maintenance is essential for uninterrupted production, so choose a machine designed for easy access to parts and components. Additionally, check for customer reviews and case studies to gauge reliability and customer satisfaction. Choosing the right Doy Pack machine can significantly influence your overall production efficiency and product quality.

Strategies for Integrating Doy Pack Machines into Your Existing Production Line

Integrating Doy Pack machines into your existing production line can significantly enhance operational efficiency, especially in packaging processes. According to industry reports, the use of automated packaging solutions like Doy Pack machines can reduce labor costs by up to 30%, while simultaneously increasing production speed and accuracy. With the capability to operate in high-speed environments, these machines can fulfill up to 200 packs per minute, thus minimizing downtime and maximizing output.

To effectively incorporate Doy Pack machines into your production line, it is essential to conduct a thorough analysis of your current setup. This includes assessing the compatibility of the new machinery with existing systems, such as conveyors and filling machines. Research indicates that companies that invest in seamless integration strategies can expect a return on investment (ROI) of approximately 20-25% within the first year of implementation. Moreover, employing real-time monitoring tools can help optimize performance, allowing managers to make informed adjustments that further enhance efficiency and product quality.

Best Practices for Maintenance and Optimization of Doy Pack Machines

To achieve maximum efficiency in your production line, regular maintenance and optimization of Doy Pack machines are critical. According to a recent report by Smithers Pira, utilizing properly maintained packaging machinery can enhance throughput by up to 30%. This efficiency gain not only minimizes downtime but also reduces operational costs, underscoring the importance of a systematic maintenance schedule. Implementing routine inspections, lubrication, and calibrations based on the manufacturer's recommendations can prevent unexpected malfunctions and prolong the life of the equipment.

In addition to maintenance, optimizing the machine's settings based on product specifications can further enhance performance. The Food and Beverage Packaging Market Report highlights that adjustments in fill volume, sealing temperatures, and conveyor speed can lead to a 15% increase in production rates. Moreover, training staff on best practices for operating Doy Pack machines can significantly reduce waste and improve product integrity, ensuring that the packaging process is not only efficient but also sustainable. By prioritizing maintenance and optimization, manufacturers can fully leverage the capabilities of Doy Pack machines, positioning themselves competitively in the market.

Production Line Efficiency Optimization with Doy Pack Machines

Measuring Efficiency: KPIs for Assessing Your Doy Pack Machine Performance

When it comes to optimizing production lines with a Doy Pack machine, measuring efficiency is crucial. Key Performance Indicators (KPIs) are essential tools for assessing the performance of your packaging equipment. Important KPIs to consider include production output, machine downtime, and packaging accuracy. By analyzing these metrics, you can identify bottlenecks in the workflow, ensuring resources are allocated effectively and production goals are met.

Another vital KPI is overall equipment effectiveness (OEE), which combines availability, performance, and quality into a single metric. Monitoring OEE allows you to pinpoint areas for improvement. Additionally, assessing the rate of product defects and rework cycles can provide insights into the machine's precision and reliability. For continuous enhancement, regularly reviewing these performance indicators can help in fine-tuning operations, leading to increased efficiency and reduced waste in your production line with the Doy Pack machine.

How to Optimize Your Production Line with a Doy Pack Machine for Maximum Efficiency - Measuring Efficiency: KPIs for Assessing Your Doy Pack Machine Performance

| KPI | Description | Current Value | Target Value | Status |

|---|---|---|---|---|

| Production Output | The total units produced by the Doy Pack machine | 1000 units | 1200 units | Below Target |

| Downtime | Total time the machine is not operational | 2 hours | 1 hour | Above Target |

| Machine Efficiency | Percentage of time the machine is productive | 85% | 90% | Below Target |

| Product Quality | Percentage of products passing quality inspection | 95% | 98% | Below Target |

| Spare Parts Usage | Amount of spare parts used during production | 5 parts | 3 parts | Above Target |

Related Posts

-

Unlocking the Advantages of Best Flexible Packaging Machines for Global Buyers

-

Maximizing ROI: How the Best Food Pouch Machine Ensures Low Maintenance Costs and Superior After-Sales Support

-

Navigating the 2025 Trends in Best Packaging Equipment for Global Buyers to Enhance Efficiency

-

How to Choose the Right Flexible Packaging Machines for Your Production Needs

-

The Future of Innovative Flexible Packaging Machines for Sustainable Solutions

-

How to Optimize Your Food Packaging Process with Advanced Machine Technology