What Is Pack Machinery and Why Is It Essential for Your Business?

In today's fast-paced industrial landscape, the role of pack machinery has become increasingly critical for businesses seeking efficiency and reliability in their operations. As John Smith, a leading expert in pack machinery, aptly stated, "The right packing equipment not only streamlines production processes but also significantly enhances product integrity and customer satisfaction." This assertion underscores the fundamental importance of investing in quality packing solutions for any competitive business.

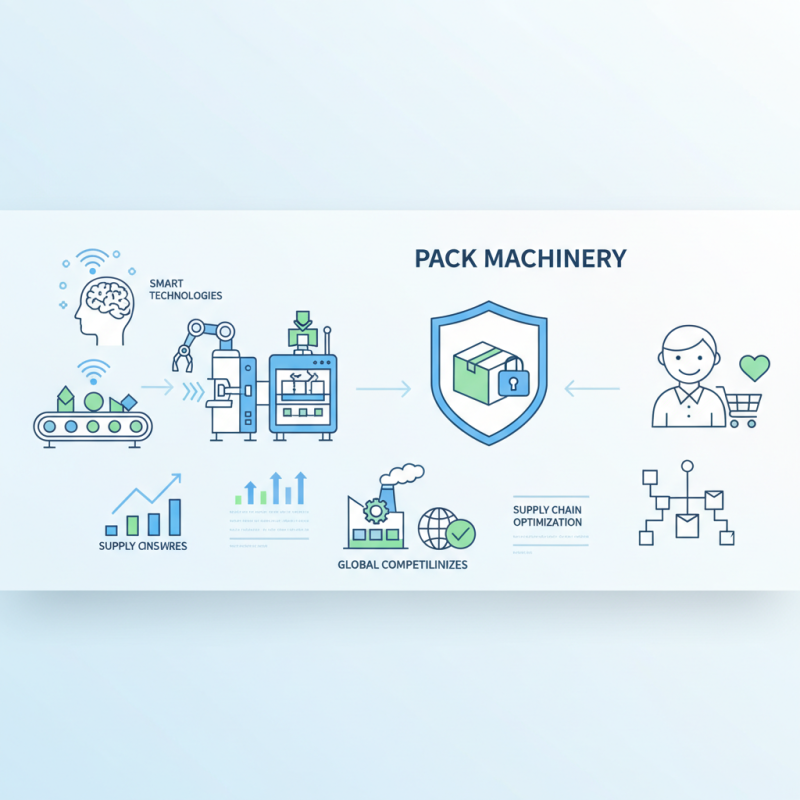

In pack machinery, innovation and technology play pivotal roles that extend far beyond mere packaging. Companies are now harnessing automation and smart technologies to optimize not only the packing process but also the overall supply chain. As businesses strive to meet escalating consumer demands, understanding the nuances of pack machinery becomes essential for maintaining a competitive edge. This article will delve into the various facets of pack machinery, highlighting its significance, technological advancements, and best practices for implementation. With the right knowledge and tools, businesses can leverage packing solutions to not only improve productivity but also drive growth and customer loyalty.

Understanding Pack Machinery: Definition and Overview

Pack machinery refers to equipment specifically designed for packaging goods across various industries, playing a pivotal role in the supply chain. The global packaging machinery market was valued at approximately $40 billion in 2021 and is projected to grow significantly, driven by the rising demand for efficient packaging solutions and the expansion of e-commerce. This growth underscores the importance of investing in advanced packing technology to increase productivity, reduce waste, and improve product safety.

With advancements in automation and robotics, modern pack machinery offers enhanced efficiency and precision. According to a report by Smithers Pira, automated packaging solutions can increase production speeds by up to 50%, while minimizing human error and operational costs. Industries such as food and beverage, pharmaceuticals, and consumer goods benefit tremendously from these innovations, as they require speed and reliability in their packaging processes to meet consumer demands. Thus, understanding pack machinery is essential for businesses aiming to remain competitive in an increasingly fast-paced market.

The Importance of Pack Machinery in Modern Business Operations

In today's fast-paced business environment, pack machinery plays a pivotal role in ensuring efficiency and productivity across various industries. The use of advanced packing equipment can significantly streamline operations, reduce labor costs, and minimize human error. By automating the packing process, companies can handle larger volumes of products faster, allowing them to meet consumer demands more effectively and stay competitive in the market.

Furthermore, modern pack machinery enhances product safety and integrity. With sophisticated technologies designed for precision, businesses can ensure that their goods are perfectly sealed and protected from damage during transportation and storage. This not only boosts customer satisfaction but also strengthens brand loyalty, as consumers increasingly expect high-quality and reliable products. As businesses strive to optimize their supply chains, investing in pack machinery is becoming essential for maintaining operational excellence and meeting the expectations of a discerning market.

Key Components and Types of Pack Machinery Explained

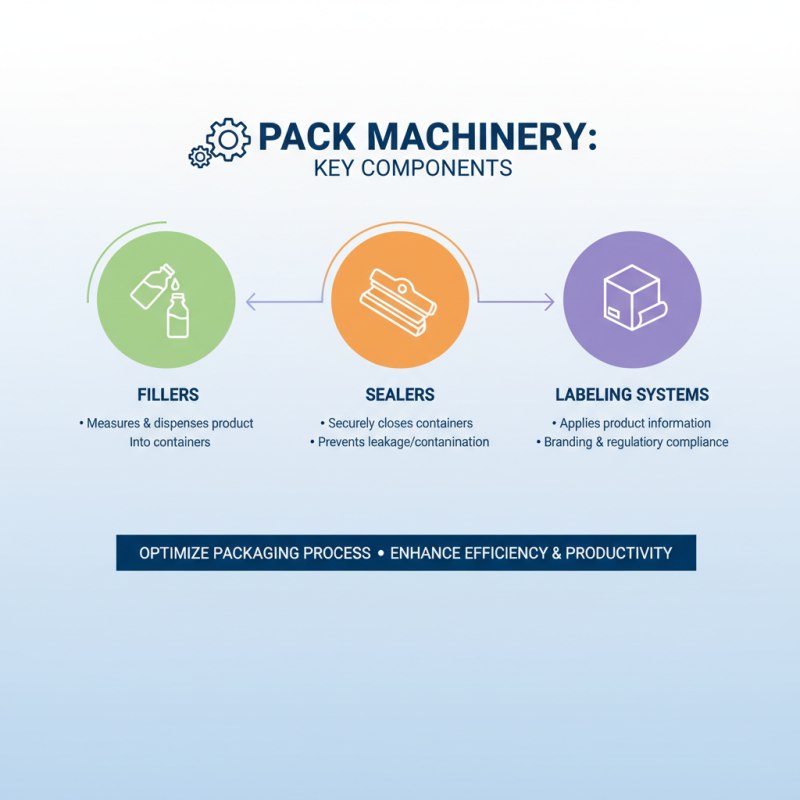

Pack machinery encompasses a variety of equipment designed to optimize the packaging process for various products. Understanding the key components and types of pack machinery is essential for any business looking to enhance efficiency and productivity. The primary components of pack machinery typically include fillers, sealers, and labeling systems. Fillers are responsible for measuring and dispensing the product into containers, while sealers ensure that these containers are securely closed to prevent leakage or contamination. Labeling systems, on the other hand, provide necessary information about the product, helping to brand the product effectively while also complying with regulatory requirements.

There are several types of pack machinery tailored to meet the needs of different industries. For instance, vertical form-fill-seal machines are widely used for packaging food products, allowing for rapid production by forming bags from flat film and filling them with the desired contents. Similarly, cartoning machines are essential in industries that require the packaging of products into cartons for easier handling and transportation. Additionally, shrink wrapping machines provide a tamper-proof seal around products, enhancing security and preservation. By utilizing the right types of pack machinery, businesses can significantly improve their packaging processes, leading to better productivity, reduced operational costs, and increased customer satisfaction.

Benefits of Implementing Pack Machinery in Your Production Line

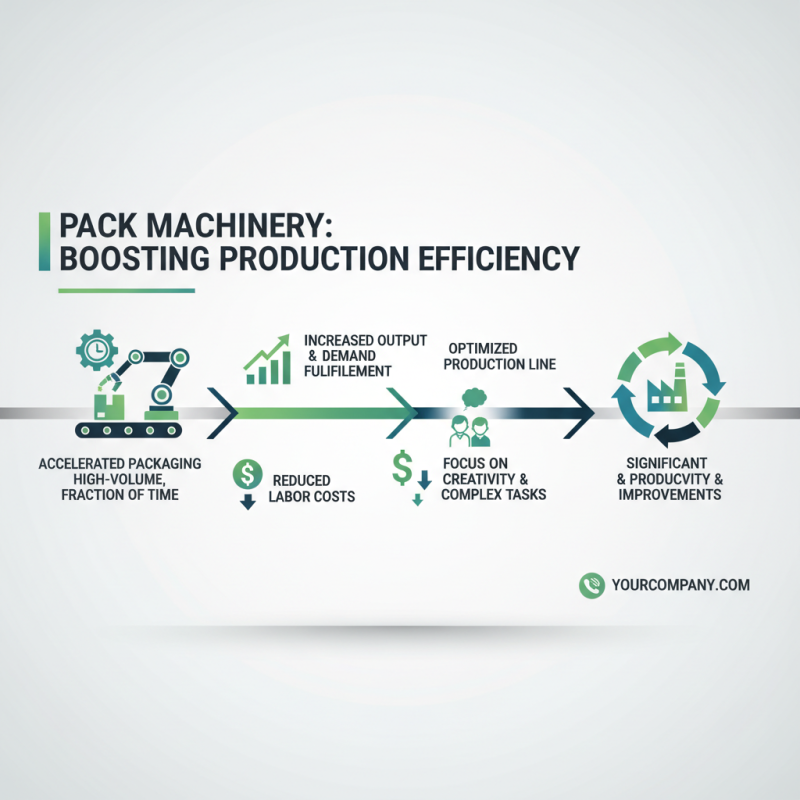

Implementing pack machinery in your production line can lead to significant improvements in efficiency and productivity. One of the primary benefits is the acceleration of the packaging process. Automated packing systems can handle a high volume of products in a fraction of the time it would take for manual labor, allowing businesses to meet increased demand without compromising quality. This swift process not only increases output but also reduces labor costs, freeing up human resources for more complex tasks that require critical thinking and creativity.

Another advantage of pack machinery is its ability to enhance consistency and reduce errors in packaging. Automated systems are programmed to perform repetitive tasks with precision, ensuring that each package meets the required standards. This consistency improves the overall quality of the product and increases customer satisfaction. Additionally, reliable packaging systems can minimize material waste through better accuracy and optimization, thus contributing to cost savings. Overall, by integrating pack machinery into production lines, businesses can achieve greater efficiency, higher quality output, and ultimately, increased profitability.

Factors to Consider When Choosing Pack Machinery for Your Business

When selecting pack machinery for your business, several key factors warrant careful consideration to ensure optimal performance and efficiency. First and foremost, it is essential to evaluate the specific needs of your production line. This involves understanding the types of products being packaged, the required speed of operation, and the level of automation desired. Different industries have unique requirements; therefore, customizing your equipment choices to fit your product characteristics will enhance the packaging process and reduce waste.

Another critical aspect to consider is the scalability of the machinery. As your business grows, so will your production demands. Choosing equipment that can be easily upgraded or expanded will save time and resources in the long run. Additionally, it is important to assess the reliability and durability of the machinery. Investing in high-quality, robust machines will minimize downtime and maintenance costs, ultimately leading to a more profitable operation. By focusing on these key factors, you can make informed decisions that will benefit your business now and in the future.

Importance of Pack Machinery for Your Business

Related Posts

-

How to Optimize Your Food Packaging Process with Advanced Machine Technology

-

Top Trends in Pack Machinery for 2025: What to Expect and How to Prepare

-

Unlocking the Advantages of Best Flexible Packaging Machines for Global Buyers

-

The Future of Innovative Flexible Packaging Machines for Sustainable Solutions

-

Unmatched Quality from China's Premier Factories Establishing Global Trust in the Best Wrapping Machine

-

Premier Chinese Factory Delivers Exceptional Packaging Equipment and Machinery Worldwide