Revolutionizing Packaging: The Future of Cartoning Machines in Modern Manufacturing

In the ever-evolving landscape of modern manufacturing, the role of cartoning machines has become pivotal in redefining packaging processes. These automated systems are not only streamlining production lines but also enhancing efficiency and reducing operational costs. As industries strive for sustainability and speed, cartoning machines are emerging as essential tools that facilitate faster packaging while maintaining product integrity and quality.

This article explores the transformative impact of cartoning machines on the packaging sector, highlighting innovations that allow manufacturers to adapt to changing market demands and consumer preferences. By examining the technological advancements and future trends in cartoning machinery, we can better understand how these machines are revolutionizing the packaging landscape and setting the stage for a more efficient and eco-friendly manufacturing era.

The Rise of Smart Cartoning Machines in the Industry

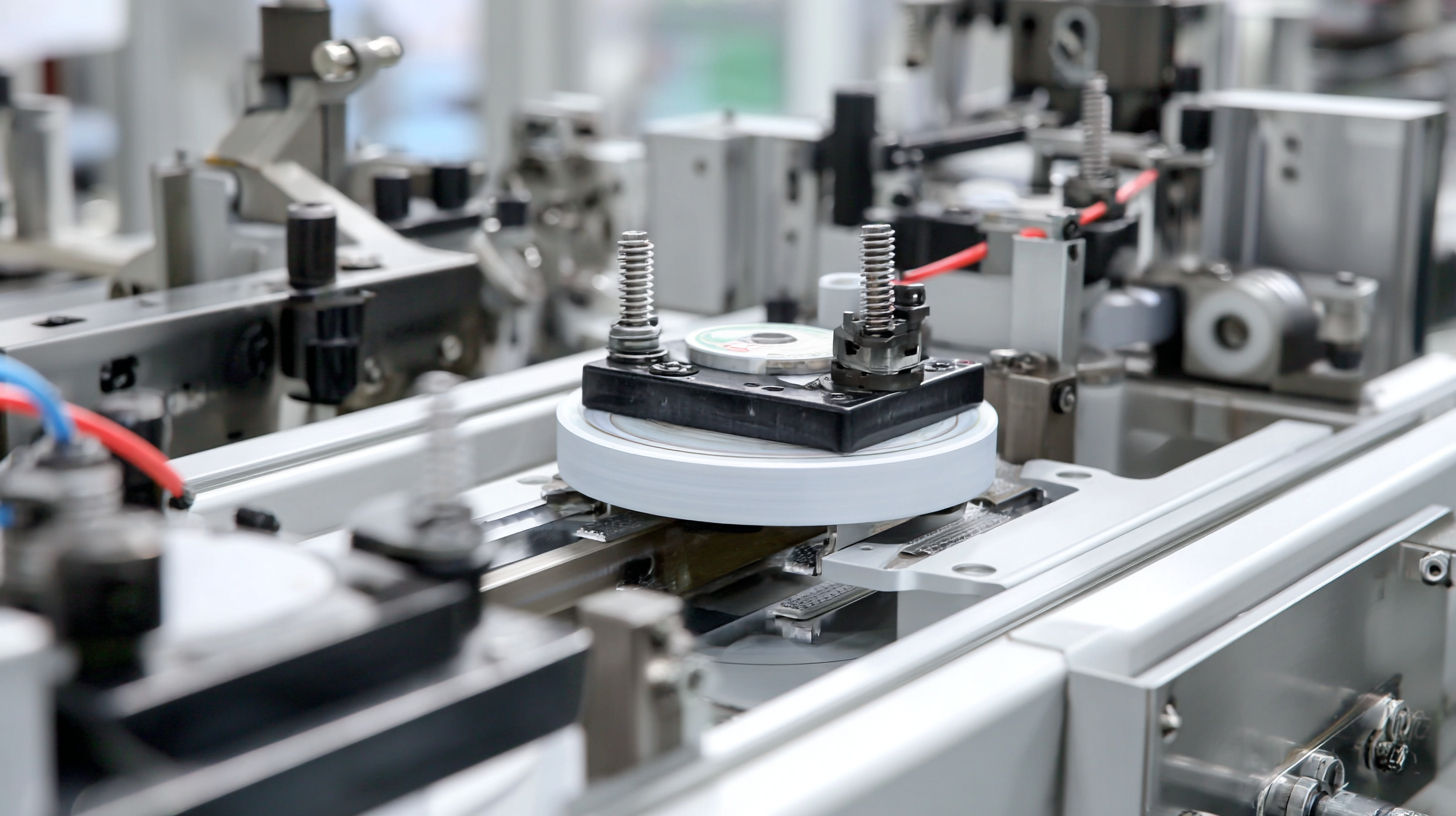

The rise of smart cartoning machines represents a significant transformation in the packaging industry, driven by advancements in artificial intelligence (AI). These machines leverage cutting-edge technologies such as machine learning and computer vision to enhance their operational efficiency. By analyzing data in real-time, they can predict demand fluctuations, optimize packaging layouts, and minimize material waste. This not only streamlines production processes but also contributes to sustainability efforts within the industry.

Moreover, smart cartoning machines are capable of adapting to various product types and sizes, making them versatile tools in modern manufacturing. Natural language processing further aids in user interaction, allowing operators to communicate with the machines more intuitively. As manufacturers increasingly adopt these smart solutions, they can expect higher accuracy, reduced downtime, and improved overall productivity. The integration of predictive analysis and AI within cartoning systems is setting new standards for efficiency and adaptability, positioning them as indispensable in the evolving landscape of packaging technologies.

Integrating IoT for Enhanced Manufacturing Efficiency

The integration of IoT in manufacturing is set to revolutionize the sector, significantly enhancing efficiency and operational capabilities. By 2032, the global IoT market is projected to surge to $40623.4 billion, reflecting a robust compound annual growth rate (CAGR) of 24.30% from its estimated $7144.8 billion in 2024. In this evolving landscape, integrating advanced technologies such as predictive maintenance solutions will play a crucial role in optimizing operations and minimizing downtime. The predictive maintenance market anticipates significant growth, aided by IoT innovations, which leverage real-time data for better decision-making.

**Tip:** Companies should evaluate their current infrastructure and identify areas where IoT can be deployed to enhance operational efficiency. This strategic integration can lead to substantial cost savings and improved service quality.

Moreover, the IoT connectivity market is expected to swell from $23.55 billion in 2023 to an estimated $65 billion by 2032, indicating a CAGR of 11.94%. Such growth signals the increasing dependency on connected devices and their role in data collection and analysis across the manufacturing floor. Deploying IoT solutions, whether through cloud or on-premises systems, can provide businesses with deeper insights into their operations and enhance responsiveness to market demands.

**Tip:** Leveraging cloud-based IoT solutions can offer scalability advantages and reduce upfront costs, making it easier for both large enterprises and SMEs to adopt and benefit from IoT technologies.

Sustainable Packaging Solutions Through Advanced Cartoning Technology

As industries increasingly pivot towards sustainability, advanced cartoning technology is leading the way in revolutionizing packaging solutions. The rising demand for environmentally friendly products has paved the path for innovative cartoning machines that minimize waste and enhance efficiency. These modern machines are engineered to use eco-friendly materials, optimizing the use of recyclable and biodegradable resources, which helps companies meet stringent environmental regulations while appealing to a conscientious consumer base.

Moreover, with advancements in automation and smart technology, these cartoning systems now offer enhanced functionality. They are capable of adapting to various product types and sizes, thus reducing the need for excess packaging and contributing to more sustainable practices. By integrating real-time monitoring and data analytics, manufacturers can further streamline their operations, lowering energy consumption and improving productivity. As a result, the future of packaging is not only about protecting products but also about protecting the planet, making advanced cartoning technology a critical player in the quest for sustainable manufacturing solutions.

Leveraging AI for Predictive Maintenance and Production Optimization

The integration of digital twin technology is transforming the landscape of modern manufacturing, particularly in the realm of cartoning machines. By harnessing advanced simulation design and high-resolution modeling, manufacturers can achieve precise and efficient production processes. This not only enhances the accuracy of machine operations but also significantly reduces downtime through AI-driven predictive maintenance. Recent industry reports indicate that companies employing digital twin technology have seen an increase in operational efficiency by up to 30%, underscoring its importance in optimizing production.

Tips: To fully leverage the benefits of digital twin technology, manufacturers should invest in training for their teams to understand and utilize these advanced tools effectively. Additionally, incorporating real-time data analysis will enable quicker decision-making and enhance overall productivity.

Moreover, innovative applications like product design and testing are now possible with the real-time insights provided by digital twins. This allows manufacturers to simulate various production scenarios, fine-tune processes, and preemptively address potential issues before they arise in the actual production line. As the manufacturing sector continues to embrace these technologies, the ability to innovate and adapt will play a crucial role in staying competitive in a rapidly evolving market.

Tips: Regularly updating digital twins with new data can provide ongoing insights, ensuring that manufacturers remain agile and responsive to market demands.

Future Trends: Automation and Customization in Cartoning Solutions

The landscape of cartoning solutions is evolving rapidly, driven by the dual forces of automation and customization. According to a recent report by Smithers Pira, the global market for packaging automation is expected to grow at a CAGR of 7.5% from 2021 to 2026, indicating a strong shift towards automated processes in manufacturing. As industries strive for efficiency and reduced labor costs, cartoning machines are being integrated with advanced robotics and artificial intelligence to optimize production lines. This trend not only enhances speed but also minimizes human error, aligning with the increasing demand for higher quality standards in consumer goods.

Customization is another pivotal trend reshaping the cartoning sector. A study by Grand View Research highlights that 70% of consumers prefer personalized packaging, compelling manufacturers to adapt their cartoning solutions. This shift requires machines that can handle short runs and diverse SKU variations without sacrificing efficiency. Modern cartoning machines are now designed with flexible features that allow for swift changes between different product sizes and shapes, catering to the dynamic needs of brands. As a result, businesses that embrace both automation and customization can not only streamline their operations but also create unique experiences that resonate with consumers, setting them apart in a competitive marketplace.

Revolutionizing Packaging: The Future of Cartoning Machines in Modern Manufacturing

| Feature | Current Trends | Future Innovations |

|---|---|---|

| Automation | Increased use of robotics for packing processes | Fully automated and AI-driven cartoning systems |

| Customization | Standardized cartoning sizes and shapes | On-demand customization for unique product shapes |

| Sustainability | Use of recyclable materials for packaging | Development of biodegradable packaging solutions |

| Speed and Efficiency | Increased machine speeds for high-volume production | Adaptive systems for optimal efficiency at varying loads |

| Integration with IoT | Basic connectivity for monitoring performance | Advanced IoT integration for real-time analytics and maintenance |

Related Posts

-

Understanding the Unique Features and Applications of Best Cartoning Equipment for Your Packaging Needs

-

Leading the World with Quality Chinese Food Packaging Solutions

-

Maximizing ROI: How the Best Food Pouch Machine Ensures Low Maintenance Costs and Superior After-Sales Support

-

Ultimate Checklist for Selecting the Best Doy Pack Machine for Your Business

-

Unlocking Efficiency: Exploring the Versatile Applications and Benefits of the Best Package Machines in Global Industries

-

How to Choose the Right Flexible Packaging Machines for Your Production Needs