Top 10 Food Packaging Machines for Your Business Needs?

In today’s competitive market, investing in a food packaging machine is crucial. It enhances efficiency and maintains product quality. However, selecting the right machine can be overwhelming. Each business has its unique needs, and the choice of packaging machinery plays a significant role.

There are various types of food packaging machines available. Some focus on sealing, while others specialize in filling or labeling. This diversity can confuse many entrepreneurs. A lack of clarity often leads to mistakes in purchasing the wrong equipment.

Understanding the specific requirements of your business is essential. You may need to consider production speed, material compatibility, and budget constraints. Sometimes, businesses compromise on quality for a lower cost. This choice can result in future losses. Investing in a quality food packaging machine is an investment in your brand's future.

Overview of Food Packaging Machines and Their Importance

Food packaging machines play a critical role in the food industry. They help maintain freshness and safety. According to the latest market reports, the global food packaging machinery market is expected to reach $50 billion by 2027. This growth highlights the increasing importance of efficient packaging solutions.

Proper packaging ensures food products are protected from external contaminants. It reduces food waste and extends shelf life. Statistics show that effective packaging can decrease spoilage by up to 30%. However, companies often overlook maintenance. Neglecting regular checks can lead to production delays.

Investing in high-quality machines is vital. The right equipment can improve productivity and reduce costs. Yet, many businesses struggle to choose the best options. They fail to assess their specific needs. Without understanding their requirements, companies might invest in inefficient solutions. Striking the right balance is essential for long-term success.

Criteria for Selecting the Best Food Packaging Machines for Your Business

Choosing the right food packaging machine is crucial. Several factors come into play. Consider the type of food you’re packaging. Different products require different types of sealing and materials. For example, liquids need better sealing options to prevent leaks. Solid foods, on the other hand, might require more durable packaging.

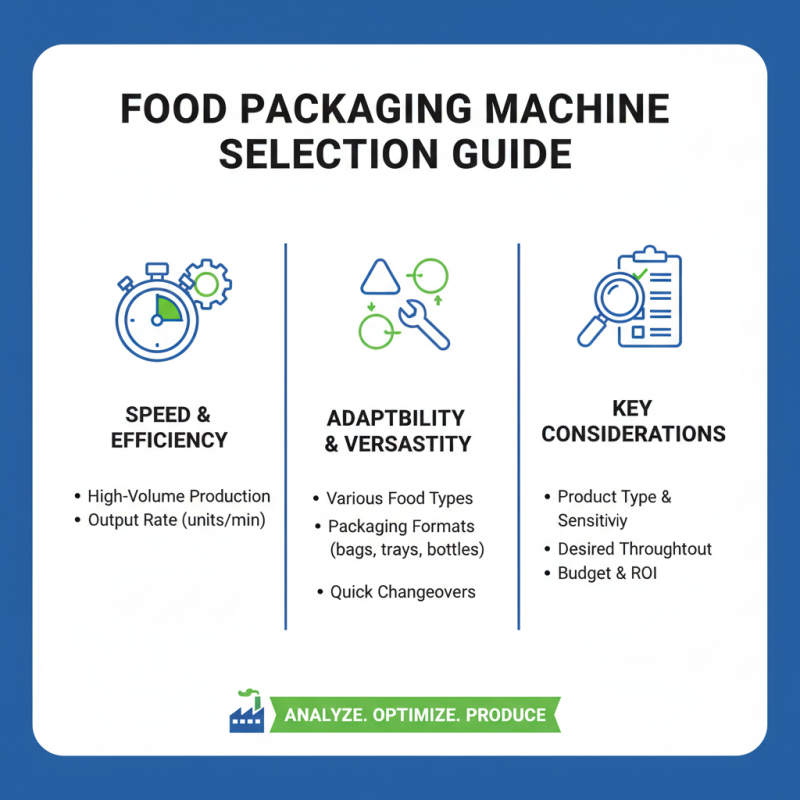

Next, evaluate the machine’s speed and efficiency. High production rates can boost your business. Look for machines that offer quick changeover times for different products. This flexibility can save time and reduce operational costs. Training staff on new machines can be challenging. It's essential to pick user-friendly models to ease the transition.

Don’t overlook the price and warranty. Budget constraints always matter. Sometimes, higher upfront costs can lead to better long-term savings. Warranties give peace of mind but can also reflect the machine’s quality. Factor in maintenance costs too. A cheap machine can often lead to higher repair expenses. Think critically about these details before making your final decision.

Top 10 Food Packaging Machines by Speed and Efficiency

Top 10 Food Packaging Machines: Features and Specifications

When selecting food packaging machines, understanding features and specifications is crucial. Different machines offer various capabilities. Some are designed for high-speed packaging, while others focus on versatility. This can greatly impact production efficiency.

Consider machines that handle diverse package types. This means accommodating different sizes and materials. A machine that can switch between bags, pouches, and boxes saves time. Flexibility is vital in meeting varying customer demands. However, it's important to note that complexities in operation may arise. Training staff can become a concern.

Another key aspect is the machine’s automation level. Fully automatic machines significantly reduce labor costs. They streamline the packaging process. But, more automation can also mean higher initial investments. Assessing return on investment is essential. User-friendly interfaces can reduce the learning curve, but sometimes, they may lack advanced features. Online reviews often highlight these trade-offs. Balancing cost, efficiency, and ease of use is a challenge for businesses.

Top 10 Food Packaging Machines for Your Business Needs

| Machine Model | Type | Speed (packages/min) | Dimensions (L x W x H) | Weight (kg) | Power (kW) |

|---|---|---|---|---|---|

| Model A | Vertical Form Fill Seal | 60 | 1200 x 800 x 1800 mm | 150 | 3.0 |

| Model B | Horizontal Flow Wrapper | 80 | 1500 x 1000 x 2000 mm | 200 | 4.5 |

| Model C | Vacuum Packaging Machine | 30 | 1000 x 700 x 900 mm | 100 | 2.0 |

| Model D | Carton Sealing Machine | 50 | 1300 x 900 x 1500 mm | 250 | 3.5 |

| Model E | Pouch Packaging Machine | 70 | 1100 x 800 x 1600 mm | 180 | 3.2 |

| Model F | Labeling Machine | 100 | 800 x 600 x 1200 mm | 90 | 1.5 |

| Model G | Shrink Wrapping Machine | 40 | 1300 x 700 x 1800 mm | 210 | 3.8 |

| Model H | Filling Machine | 120 | 1150 x 900 x 1700 mm | 160 | 4.0 |

| Model I | Thermoforming Machine | 20 | 1900 x 1000 x 2200 mm | 300 | 5.5 |

| Model J | Cartoning Machine | 25 | 1400 x 1000 x 1800 mm | 220 | 3.7 |

Comparative Analysis of Leading Food Packaging Machine Brands

When selecting food packaging machines, many factors come into play. Speed, efficiency, and adaptability are critical. Some machines excel in high-volume production. Others offer versatility for various food products. It’s essential to analyze these features thoroughly.

Costs can vary significantly. Some budget options may sacrifice quality. Investing in premium machines can boost productivity. However, not all expensive machines provide the same value. Research and testing are necessary to avoid pitfalls. User experiences often highlight flaws in specific models. Maintenance needs can also differ.

Packaging styles matter too. Some machines focus on vacuum sealing, while others provide shrink wrapping. The right choice depends on your product type. Ergonomics play a role in usability, impacting employee efficiency. It’s crucial to ensure the machine fits your workspace. Always consider the sustainability of the materials used. Opt for eco-friendly options when possible, though this can increase costs.

Future Trends in Food Packaging Technology and Machinery

The food packaging industry is evolving rapidly. Advanced technologies are shaping how businesses approach packaging. A recent report by MarketsandMarkets predicts the global food packaging market will reach $500 billion by 2026. This growth is driven by rising consumer demand for sustainable and innovative solutions.

Automation in packaging is becoming more prominent. Many companies now use robotic systems to improve efficiency. In fact, a study shows that automation can reduce packaging costs by 20%. However, not all businesses have access to these technologies, leading to disparities in the market. Smaller producers often struggle to keep up with larger competitors.

Sustainability is another key focus. Consumers are demanding eco-friendly packaging that reduces waste. To meet these expectations, companies are investing in biodegradable materials. However, the transition is not without challenges. Some businesses find it hard to balance cost and sustainability. This ongoing struggle reflects a need for continuous improvement in the food packaging sector.

Related Posts

-

Unlocking the Advantages of Best Flexible Packaging Machines for Global Buyers

-

Exploring Innovative Food Packaging Machine Types: Industry Trends and Data Insights

-

Premier Chinese Factory Delivers Exceptional Packaging Equipment and Machinery Worldwide

-

Global Reach of Chinese Manufacturing in Best Packaging Equipment with Trusted Quality Standards

-

How to Choose the Right Flexible Packaging Machines for Your Production Needs

-

7 Essential Tips for Choosing the Best Coffee Packaging Equipment