Top Wrapping Machine Types for 2026 What to Choose?

In the evolving packaging landscape, the wrapping machine segment stands out with its technological advancements. According to a recent market analysis by Smith & Associates, the wrapping machine industry is projected to grow by 12% annually through 2026. This growth indicates a rising demand for efficient and innovative solutions across various sectors.

Industry expert Dr. Emily Chen emphasizes the importance of choosing the right wrapping machine: "The machine you select can significantly impact both productivity and sustainability." This statement reflects the pressing need for businesses to consider not only efficiency but also environmental impact. With various options available, businesses face challenges in selecting an appropriate machine that aligns with their operational goals.

As firms navigate this competitive environment, the decision-making process can be overwhelming. Factors such as machine size, speed, and technology integration must be evaluated. Traditional wrapping solutions often fall short in adaptability. Therefore, companies need to reassess their packaging strategies to stay relevant and competitive. The future of packaging lies in aligning innovative wrapping machines with sustainability goals.

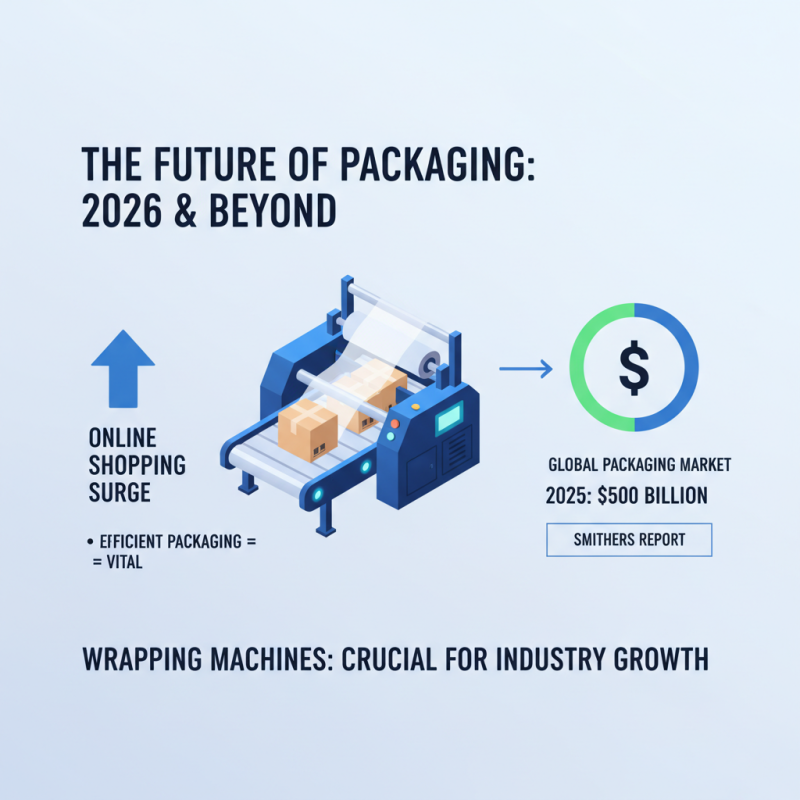

Overview of the Importance of Wrapping Machines in 2026

In 2026, wrapping machines will play a crucial role in various industries. With online shopping surging, efficient packaging is vital. A recent report from Smithers indicated that the global packaging market is predicted to reach $500 billion by 2025. This uptick reflects the growing need for effective wrapping solutions.

The operational efficiency of wrapping machines directly influences product protection and shelf appeal. There are various types. Stretch wrappers, for instance, are favored for their speed and versatility. They can wrap pallets in seconds, reducing labor costs. However, businesses must balance speed with precision; otherwise, products risk damage during transit.

Sustainability is also a pressing issue. Many companies are shifting to eco-friendly materials. The global sustainable packaging market is expected to grow to $400 billion by 2027. This trend reveals an urgent need for machines that can handle recyclable materials well. Yet, not all wrapping machines are equipped for this transition. Companies face challenges in upgrading their old systems to meet these new demands. The future of wrapping machines hinges on innovation and adaptability.

Key Factors to Consider When Choosing a Wrapping Machine

When choosing a wrapper machine, several key factors come into play. First, consider the machine's speed. Reports indicate that high-speed machines can boost productivity by up to 30%. However, faster does not always mean better for your product. Some items may require gentler handling to avoid damage.

The size and type of products also matter. Wraps for smaller items differ greatly from those for bulk packaging. The market has seen an increase in demand for small-batch machines, reflecting a trend towards customization. Up to 60% of businesses report a preference for equipment that can handle versatile packaging needs.

Another crucial aspect is the type of wrapping material used. Advanced films can reduce waste and improve sealing quality. A study by industry analysts shows that using eco-friendly materials can enhance brand image. Yet, finding the balance between quality and sustainability remains a challenge for many companies. This reflection is essential in making a thoughtful selection for your wrapping needs.

Types of Wrapping Machines: An In-Depth Analysis

When exploring wrapping machines, understanding different types is essential. A major report from the Packaging Machinery Manufacturers Institute (PMMI) states that the demand for automatic wrapping machines is increasing. This shift indicates a trend towards efficiency and automation. The market for wrapping machines is projected to grow significantly, valued at over $7 billion by 2026.

Manual wrapping machines are budget-friendly but require more labor. They can be useful for small businesses. Automatic options, while more expensive, offer consistency and speed. In fact, automatic machines can increase production by up to 50%. Semi-automatic machines serve as a middle ground, combining elements of both types, though they might still require human oversight.

Tip: Assess your production needs carefully. Consider starting with a semi-automatic model if you're unsure about volume requirements. Understand the potential downsides: investing heavily in an automatic machine might not pay off if production volumes drop.

Choosing the right type can be challenging. Factors such as product size, wrapping material, and speed are critical. Misjudging these needs can lead to inefficiencies. Upgrading to advanced models may seem appealing, but evaluating the work environment and automation levels is vital. Experimenting before committing can provide valuable insights. Your choice should align with long-term goals rather than short-term excitement.

Emerging Technologies and Trends in Wrapping Machines for 2026

As we approach 2026, packaging efficiency becomes critical for businesses. Emerging technologies are reshaping wrapping machines. Automation plays a central role here. Reports indicate that by 2026, the global wrapping machine market will grow at a CAGR of 5.2%. Companies are investing heavily in these advancements.

One significant trend is the integration of AI in packaging processes. AI enhances precision and minimizes waste. It allows machines to adapt to various packaging materials easily. Additionally, the rise of e-commerce has led to an increased demand for flexible wrapping solutions. Almost 75% of companies surveyed are looking for machines that can accommodate different sizes and shapes.

However, challenges persist. Many businesses still rely on outdated technology. This reliance can lead to inefficiencies and increased costs. Adaptation is necessary, but it requires investment. It's essential to balance cutting-edge technology with practical needs. The future of wrapping machines is bright, yet it demands thoughtful reflection on existing practices.

Top Wrapping Machine Types for 2026

Cost Efficiency and Return on Investment with Modern Wrapping Solutions

The decision to invest in modern wrapping solutions often hinges on cost efficiency and return on investment. Businesses face pressure to optimize operations. A good wrapping machine should not only meet production needs but also fit budget constraints. Many options exist, from semi-automatic to fully automatic machines. Each type has its pros and cons, affecting both initial costs and operational efficiency.

Consider the differences. Semi-automatic machines may have lower upfront costs but require more labor. This can lead to hidden expenses over time. On the other hand, fully automatic machines reduce labor costs. However, they require a higher initial investment. Businesses must weigh these factors carefully. It's essential to assess throughput needs, material types, and expected changes in production.

Ultimately, understanding the total cost of ownership is crucial. Maintenance costs, energy consumption, and training needs can significantly affect profitability. While modern wrapping solutions promise efficiency, it’s not always evident. Sometimes, the most advanced option may not yield the best returns. A careful evaluation of needs is vital to making an informed decision, especially in an ever-changing market.

Related Posts

-

Unmatched Quality from China's Premier Factories Establishing Global Trust in the Best Wrapping Machine

-

Unmatched Quality from Trusted Chinese Manufacturers for the Best Package Equipment

-

Navigating the 2025 Trends in Best Packaging Equipment for Global Buyers to Enhance Efficiency

-

5 Compelling Reasons Your Business Needs the Best Packaging Equipment Today

-

7 Innovative Best Packing Equipment Solutions for Global Buyers

-

5 Essential Tips to Maximize Efficiency with Your Package Machine