Understanding the Unique Features and Applications of Best Cartoning Equipment for Your Packaging Needs

In today's competitive packaging landscape, the importance of high-quality cartoning equipment cannot be overstated. As global demand for efficient and reliable packaging solutions continues to rise, the cartoning machinery market is projected to reach USD 3.5 billion by 2024, with a compound annual growth rate (CAGR) of 6.5% from 2019 to 2024, according to a recent industry report. This surge is attributed to the increasing need for automation in packaging processes across various sectors, including food, pharmaceuticals, and consumer goods. As companies strive to enhance productivity while maintaining exceptional quality standards, investing in state-of-the-art cartoning equipment becomes crucial. Notably, "Made in China" products have gained a reputation for their unwavering quality, offering businesses a reliable option to meet their packaging demands. This blog will explore the unique features and applications of the best cartoning equipment available today, guiding you in selecting the right solutions for your specific packaging needs.

Common Challenges in Cartoning Equipment and Their Solutions

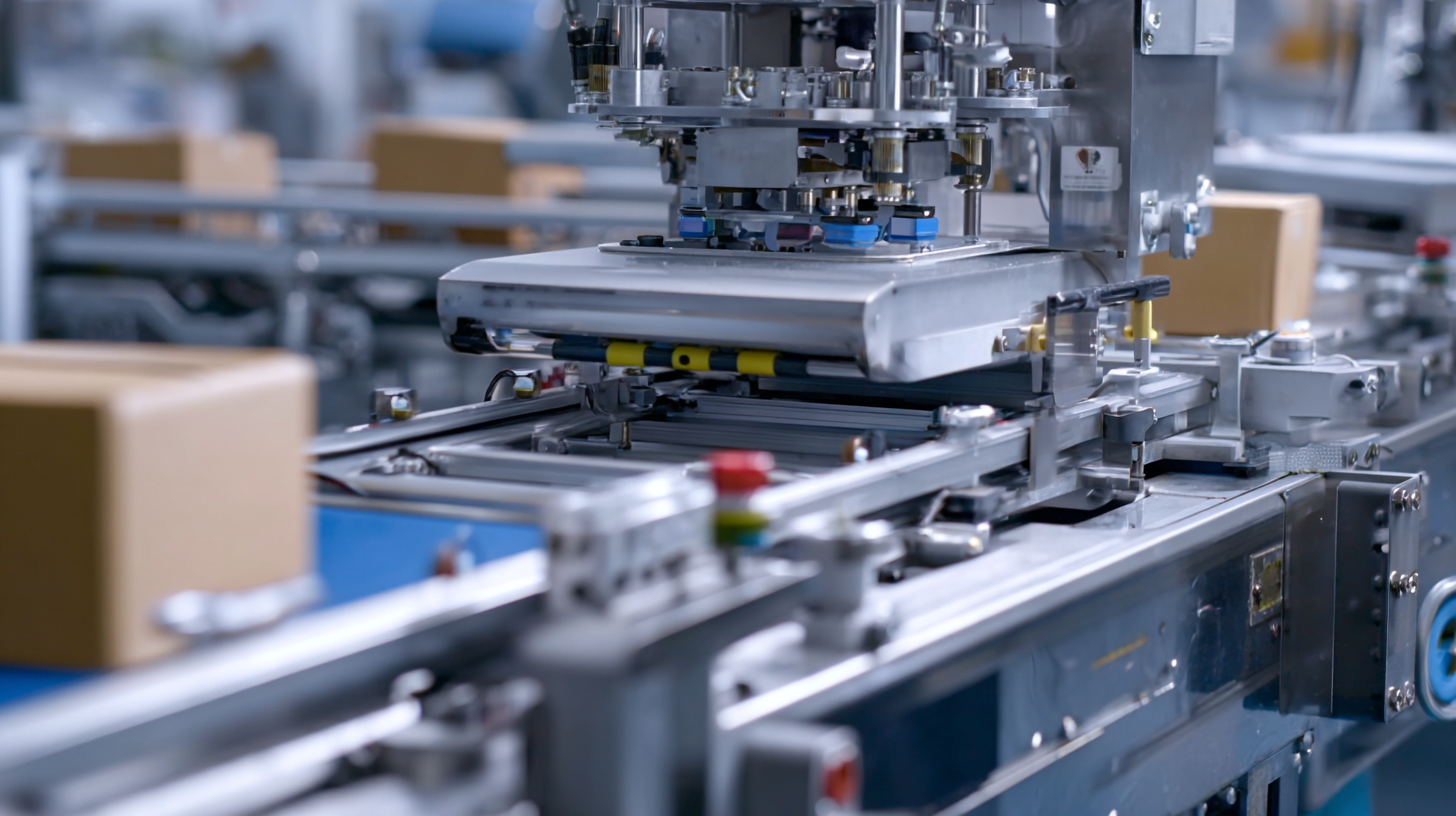

When it comes to cartoning equipment, various challenges can arise that may hinder efficiency and productivity. One common issue is the misalignment of cartons during the packaging process. This misalignment not only slows down operations but can also lead to product damage. To address this, implementing automated systems with sensors can help ensure precise carton placement and alignment, minimizing the likelihood of errors.

Another prevalent challenge is the adaptability of cartoning equipment to different product sizes and shapes. As businesses often deal with a variety of products, the ability to quickly adjust the machinery to accommodate these differences is crucial. The solution lies in investing in flexible cartoning machines that feature adjustable settings, allowing for quick changeovers. This flexibility not only saves time but also enhances the overall efficiency of the production line, ensuring that businesses can respond swiftly to changing demands in the market.

The Importance of Choosing the Right Cartoning Equipment

Choosing the right cartoning equipment is a crucial decision for businesses aiming to enhance their packaging efficiency and product safety. According to a recent report from Smithers Pira, the global packaging machinery market is expected to reach $50 billion by 2025, with a significant portion attributed to advancements in cartoning technology. This underscores the importance of investing in high-quality equipment that can meet the evolving demands of various industries, from food and beverage to pharmaceuticals.

The selection of appropriate cartoning equipment can greatly impact operational efficiency and cost-effectiveness. For instance, semi-automatic and automatic cartoners can boost productivity by up to 30%, minimizing labor costs and reducing the likelihood of human error. Additionally, the latest models incorporate features such as adjustable speed settings and enhanced product handling capabilities. Reports from the Association for Packaging and Processing Technologies (PMMI) indicate that businesses that invest in advanced cartoning solutions can see a return on investment within just 12 to 18 months, making it a strategic move for organizations looking to maintain a competitive edge in the market.

Understanding the Unique Features and Applications of Best Cartoning Equipment for Your Packaging Needs

| Feature | Description | Applications | Material Compatibility |

|---|---|---|---|

| Speed | Ability to handle a high throughput | Food, Pharmaceuticals, Consumer Goods | Cardboard, Paperboard |

| Flexibility | Ability to switch between different box sizes and styles | Cosmetics, Electronics, Toys | Plastic, Corrugated materials |

| Automation | Integration with other machinery for a streamlined process | Manufacturing Lines, High-Volume Production | All common packing materials |

| Ease of Use | User-friendly interfaces and design for quick setup | Startups, Small to Medium Enterprises | Lightweight materials, Eco-friendly options |

| Safety Features | Safety guards and emergency stops to protect operators | Industrial Manufacturing, Hazardous materials | Durable, Shock-resistant materials |

Innovative Features in Modern Cartoning Machines

The modern cartoning machine has undergone significant advancements, enhancing its role in the packaging industry. According to a report from Smithers Pira, the global market for packaging machinery is anticipated to grow at a CAGR of 4.2% from 2021 to 2026. This growth is spearheaded by innovations in cartoning technology, which now incorporates smart features like IoT connectivity, enabling real-time monitoring and predictive maintenance. With these advancements, manufacturers can optimize machine performance, minimize downtime, and ultimately reduce costs.

Additionally, contemporary cartoning machines are designed to accommodate a wide range of product sizes and shapes, reflecting the increasing demand for versatility in packaging. Research by MarketsandMarkets indicates that the demand for automated packaging solutions is surging, with the cartoning segment expected to capture a significant share of this growth. Features such as quick-change designs facilitate rapid adjustments for different carton styles, promoting operational efficiency. Furthermore, the integration of advanced robotics enhances precision and speed, which is crucial in meeting the evolving needs of industries from food and beverage to pharmaceuticals. These innovative features not only improve productivity but also align with sustainability goals by reducing material waste through optimized cartoning processes.

Innovative Features in Modern Cartoning Machines

How to Overcome Performance Issues in Cartoning Systems

When it comes to optimizing the performance of your cartoning systems, understanding potential issues is key. Common problems can include misalignment during the cartoning process, which can cause downtime and waste. Regular maintenance and timely inspections can significantly reduce these issues. It's essential to create a preventive maintenance schedule that addresses wear and tear on key components.

When it comes to optimizing the performance of your cartoning systems, understanding potential issues is key. Common problems can include misalignment during the cartoning process, which can cause downtime and waste. Regular maintenance and timely inspections can significantly reduce these issues. It's essential to create a preventive maintenance schedule that addresses wear and tear on key components.

Tips: Always keep an eye on the lubrication levels of moving parts. Ensuring that these areas are well-maintained can prevent friction-related breakdowns. Additionally, training your operators on best practices and real-time troubleshooting can empower them to handle minor issues before they escalate.

Another performance obstacle might involve the integration of your cartoning equipment with other machinery. Poorly synchronized operations can lead to bottlenecks. Invest in technology that allows for seamless communication between machines.

Tips: Leverage modern software solutions to monitor production metrics and identify potential disconnects in your workflow. Implementing a regular review of these metrics can lead to proactive adjustments, keeping your cartoning systems running smoothly.

Applications of Cartoning Equipment Across Different Industries

Cartoning equipment plays a vital role across various industries, tailored to meet specific packaging needs. In the food and beverage sector, for instance, businesses require efficient and hygienic packaging solutions to ensure product integrity and freshness. Cartoners designed for this industry often feature stainless steel constructions to meet strict hygiene standards and to facilitate quick changeovers, allowing manufacturers to adapt to different product sizes and shapes seamlessly.

Pharmaceutical companies also benefit significantly from advanced cartoning technology. Here, the focus is on packaging that not only protects sensitive products but also complies with stringent regulatory requirements. Cartoning systems used in pharma are equipped with serialization capabilities to track and trace products through the supply chain, enhancing both security and compliance. Additionally, these machines can incorporate features such as tamper-evident seals to assure consumers of product safety.

In the cosmetics industry, the aesthetic appeal of packaging is crucial. Cartoners in this field are designed to handle unique shapes and materials, ensuring that products are packaged attractively while also maintaining efficiency. With the rise of e-commerce, cartoning equipment that can accommodate a variety of product sizes and packaging formats is becoming increasingly important, allowing brands to deliver not only quality products but also a pleasing unboxing experience for their customers.