Unlocking Efficiency with the Advantages of the Best Powder Packaging Machine

In today's fast-paced manufacturing landscape, efficiency and precision are paramount, especially in the packaging sector. The powder packaging machine stands at the forefront of this evolution, significantly enhancing productivity and ensuring consistent quality. According to a recent report by the Markets and Markets Research Group, the global powder packaging market is projected to reach USD 4.68 billion by 2025, growing at a CAGR of 5.6%. This surge underscores the critical role that advanced packaging technologies, including automated powder packaging systems, play in meeting rising consumer demands and regulatory standards.

Furthermore, with stringent import and export certifications becoming increasingly vital in ensuring product safety and compliance, understanding the advantages of deploying the best powder packaging machine is essential for manufacturers seeking to optimize their operations while adhering to industry regulations.

Understanding the Importance of Powder Packaging Machines in Various Industries

In various industries, powder packaging machines play a pivotal role in maintaining efficiency and quality control. According to a report by Packaging Strategies, the global market for powder packaging machines is projected to grow significantly, reaching a value of over $4 billion by 2026. This surge in demand is primarily driven by the food and pharmaceutical sectors, where precise dosing and contamination prevention are paramount. Efficient powder packaging not only streamlines production processes but also extends the shelf life of products.

Tips for selecting the best powder packaging machine include evaluating the type of powder being packaged, the required speed of production, and the specific packaging format needed. For example, highly aerated powders like baby formula might necessitate a machine designed for gentle handling to prevent clumping. Additionally, machinery with advanced features such as automated weighing systems can reduce labor costs and minimize the risk of human error, leading to safer and more reliable packaging outcomes.

It’s also crucial to consider the integration of technology in packaging processes. Advanced powder packaging machines equipped with IoT capabilities allow for real-time monitoring and data collection. This access to information can enhance operational efficiency and provide insights into performance metrics, thereby enabling companies to make informed decisions and adjust their production strategies as needed.

Exploring Key Features of High-Quality Powder Packaging Equipment

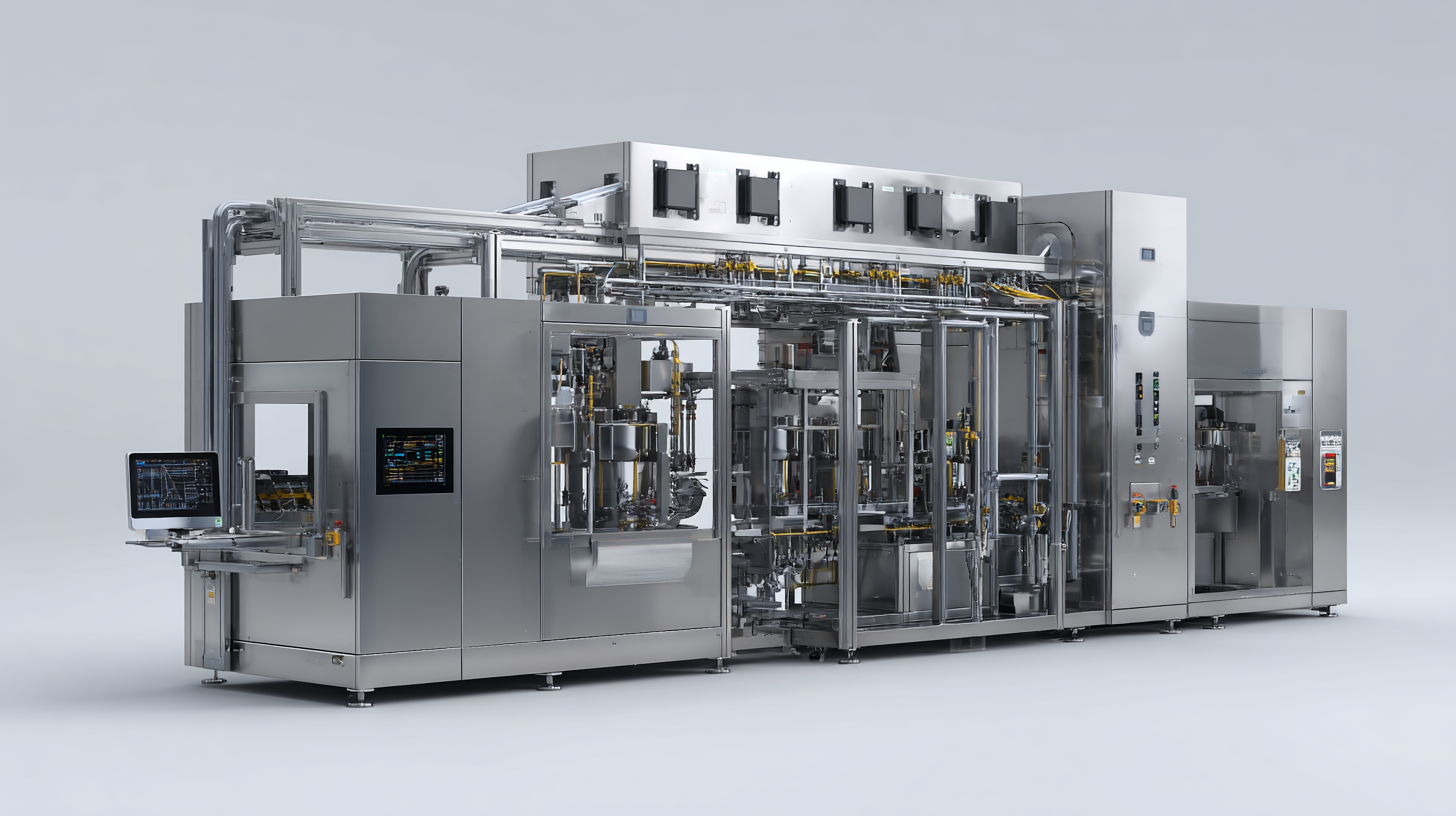

When it comes to powder packaging, investing in high-quality equipment can significantly enhance operational efficiency. One of the key features of advanced powder packaging machines is their precision filling technology. This ensures that each package is filled consistently and accurately, minimizing waste and optimizing the use of materials. Additionally, modern machines often incorporate adjustable settings that cater to various powder types, accommodating diverse particle sizes and densities without compromising performance.

Another vital aspect of top-tier powder packaging equipment is its versatility. Many of these machines can handle a range of packaging formats, such as pouches, bags, and containers, allowing businesses to diversify their product offerings. Furthermore, features like automated sealing and labeling systems streamline operations, reducing the need for manual labor and speeding up the overall production process. These enhancements not only improve the speed of packaging but also ensure that the products maintain their quality and integrity from the production line to the consumer.

The Role of Import and Export Certifications in Packaging Machinery

In today's global marketplace, the importance of import and export certifications for packaging machinery cannot be overstated. As businesses strive to enhance their operations and maintain efficiency, the right certifications serve as a testament to the quality and reliability of packaging solutions, such as powder packaging machines. Certifications ensure that equipment meets international standards, promoting safety and performance while reducing the risk of costly compliance issues. This is crucial for manufacturers looking to expand their reach into new markets where regulatory requirements may vary significantly.

Additionally, certifications facilitate smoother trade processes by simplifying customs clearance and reducing delays. When a packaging machine carries relevant certifications, it signals to regulators and customers alike that it adheres to stringent guidelines, engendering trust and confidence. For companies focused on maximizing efficiency, investing in certified packaging machinery not only enhances operational capabilities but also opens doors to new business opportunities across borders. By prioritizing certification, companies can position themselves strategically in a competitive landscape, leveraging compliance as a key advantage in their growth strategies.

Efficiency Gains: Comparing Different Powder Packaging Solutions

In the competitive landscape of powder packaging, efficiency is paramount. Different powder packaging solutions offer distinct advantages depending on the production scale and product type. According to a recent report by MarketsandMarkets, the global market for powder packaging machines is poised to grow at a CAGR of 5.8% from 2023 to 2028, driven by the increasing demand for packaged food and pharmaceuticals. Evaluating various machines based on speed, accuracy, and versatility can lead to significant efficiency gains in production processes.

When selecting a powder packaging machine, consider these tips: First, assess the machine's compatibility with your product type. For instance, granular powders require different handling compared to fine powders, impacting machine selection. Second, look for automation features that minimize human intervention, as automated machines can enhance output while reducing labor costs. Finally, invest in machines with modular designs, allowing for easy upgrades and adaptations as market demands evolve.

Comparing various powder packaging machines, you’ll find that those equipped with state-of-the-art weighing technology reduce product waste and improve accuracy. Implementing systems with advanced sensors can further streamline operations, ensuring consistent and high-quality packaging. By leveraging these insights, businesses can effectively enhance their packaging processes and drive productivity in the long run.

Unlocking Efficiency with the Advantages of the Best Powder Packaging Machine - Efficiency Gains: Comparing Different Powder Packaging Solutions

| Packaging Solution | Max Packaging Speed (bags/min) | Accuracy (%) | Automation Level | Cost (USD) |

|---|---|---|---|---|

| Machine A | 50 | 99.5 | High | 25,000 |

| Machine B | 40 | 98.0 | Medium | 20,000 |

| Machine C | 30 | 97.5 | Low | 15,000 |

| Machine D | 60 | 99.0 | High | 30,000 |

Best Practices for Selecting the Right Powder Packaging Machine for Your Business

When selecting the right powder packaging machine for your business, it is crucial to prioritize practices that ensure efficiency and quality. The ability to achieve consistent portion control is essential in the production processes of various industries, including pet food and instant coffee manufacturing. A recent report highlights that effective portioning and mixing can significantly impact the overall quality of the final product, enabling manufacturers to maintain high standards and meet consumer demand.

Additionally, understanding the specific requirements of your product can further guide your selection process. For instance, the IMARC Group’s report on instant coffee powder manufacturing outlines that investing in the right machinery and setup can streamline production and reduce costs. This is equally applicable to garlic powder production, where detailed insights point to the necessity of precision in both machinery choice and process layout to enhance operational efficiency.

Furthermore, sector-specific practices, such as vacuum conveying for pharmaceutical powders, emphasize the importance of tailoring your equipment to the material properties and facility constraints. This not only improves portion control but also adheres to stringent hygiene requirements, thus boosting the overall efficacy of the packaging process. By integrating these best practices, businesses can unlock the full potential of their powder packaging operations.