What is a Wrapping Machine and How Does It Work?

In the fast-paced world of packaging, a wrapping machine plays a crucial role. This technology helps companies streamline their operations. According to industry reports, the global wrapping machine market size was valued at over $4 billion in 2022. It is expected to grow steadily, showcasing the rising demand for efficiency.

A wrapping machine automates products' packaging, significantly reducing labor costs. It wraps goods quickly and securely, ensuring they reach consumers intact. However, not all machines meet every company's unique needs. Some may struggle with fragile items, while others may not optimize material usage. These are areas where reflection and improvement are essential.

Innovation in wrapping machines is ongoing. Manufacturers are exploring eco-friendly materials and smarter designs. Yet, challenges remain. Many businesses still face difficulties integrating new technology seamlessly. Balancing cost, efficiency, and sustainability can be tough. Therefore, understanding wrapping machines' capabilities and limitations is vital for success.

What is a Wrapping Machine?

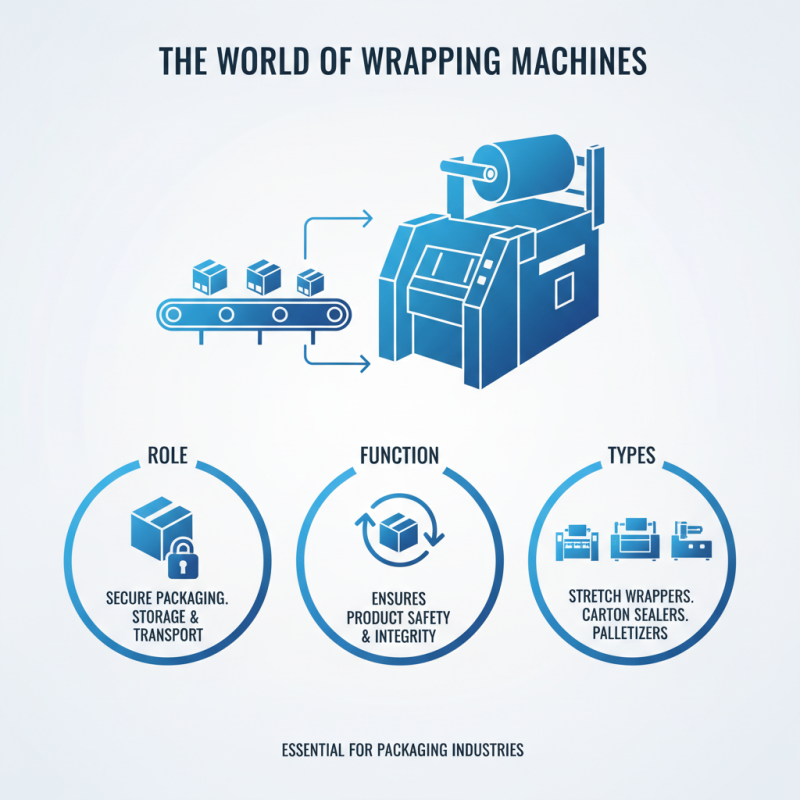

A wrapping machine is a key piece of equipment in various industries, primarily used for packaging products. These machines apply a protective layer around goods, which could be stretch film, shrink wrap, or other materials. The goal is simple: ensure safety during transport and storage. According to a recent industry report, the demand for automated wrapping solutions has grown by 15% annually, reflecting a trend towards greater efficiency in packaging practices.

These machines come in various types. For example, semi-automatic wrapping machines require some manual input, while fully automatic ones run independently. Operators need to understand the specific requirements of their products. Not all materials behave the same, and wrapping techniques may vary. Testing different methods can lead to better results.

**Tips:** Choose the right machine based on product size and type. Measure dimensions accurately. Regular maintenance of the wrapping equipment is crucial. Neglecting this can lead to downtimes and inconsistencies in wrapping quality. Poorly wrapped products might incur losses and customer dissatisfaction. Each detail matters, and small adjustments can make a significant difference.

Usage of Wrapping Machines in Various Industries

Types of Wrapping Machines Available in the Market

Wrapping machines play a crucial role in packaging industries. They ensure products are securely packaged for storage and transport. There are several types of wrapping machines available, each designed for specific needs.

One common type is the stretch wrapping machine. It uses a large roll of stretch film. The film is rotated around the product, tightly securing it. According to industry reports, the demand for stretch wrapping machines is expected to grow by over 5% annually. Another popular option is the shrink wrapping machine. This machine uses heat to shrink a film around products. It's widely used for bundling items together.

In addition, there are automatic and semi-automatic machines. Automatic machines tend to be more efficient. They require less manual labor. However, semi-automatic machines are often more affordable. Each type has its pros and cons. Companies must analyze their needs carefully.

Choosing the right wrapping machine can increase productivity. Yet, improper selection can lead to issues. Wrapping machines must align with specific production requirements. Efficiency is key, but so is flexibility. Companies may find it challenging to adapt as needs change over time.

Key Components of a Wrapping Machine

Wrapping machines are crucial in packaging industries. These machines enable efficient packaging of products, enhancing speed and reducing labor costs. Understanding their key components can help optimize their performance.

One essential component is the conveyor system. It moves products into the wrapping area smoothly. According to a recent industry report, an optimized conveyor can increase efficiency by up to 30%. Another critical part is the wrapping mechanism itself. Various types include stretch film, shrink wrap, and bagging options. Each has its pros and cons. Shrink wraps provide tight packaging but require heat, which can be a bottleneck.

Additionally, sensors play a vital role. They detect product sizes and adjust wrapping accordingly. However, sensor errors can lead to misalignment and waste. Reports show that 15% of wrapping failures are due to sensor malfunctions. Regular maintenance of these components is essential. It can prevent downtime and enhance overall productivity.

What is a Wrapping Machine and How Does It Work? - Key Components of a Wrapping Machine

| Component | Description | Function | Material Used |

|---|---|---|---|

| Wrapper Dispenser | Holds and feeds the wrapping material. | Ensures a constant supply of wrapping material. | Plastic film, paper |

| Conveyor System | Moves products through the wrapping process. | Facilitates efficient packing of multiple products. | Metal, plastic |

| Heat Sealer | Seals wrapped products through heat application. | Ensures the wrapping is tight and secure. | Metal, heat-resistant materials |

| Control Panel | Allows operators to set parameters and monitor the machine. | Provides user interface for operation management. | Plastic, metal |

| Safety Guards | Protects operators from moving parts. | Ensures workplace safety while operating the machine. | Metal, polycarbonate |

How a Wrapping Machine Operates Step-by-Step

Wrapping machines play a vital role in packaging processes across various industries. They automate the packaging of products, ensuring efficiency and consistency. The operation of a wrapping machine involves several key steps. First, the product is placed on the conveyor belt. The machine then senses the product’s presence, activating the wrapping mechanism.

Once activated, the machine dispenses the wrapping material. This could be plastic film or paper, depending on the product's needs. The material wraps around the product, creating a secure seal. In a high-speed wrapping system, the entire process can take mere seconds, allowing for the wrapping of thousands of products per hour.

Tips: Regular maintenance is crucial. Check the wrapping rolls frequently to avoid disruptions. Ensure that settings are calibrated correctly for different products. Minor adjustments might save significant time and costs.

After the product is wrapped, it moves to the cutting station. The machine cuts the wrapping material neatly, ensuring a professional appearance. However, issues can arise if the machinery is not properly calibrated. Inaccurate settings may result in wasted materials and poorly wrapped products.

By understanding the operation of wrapping machines, businesses can enhance their packaging efficiency. Investing in the right machinery and maintaining it well can impact productivity. Leveraging data from industry reports, companies can make informed choices about wrapping technologies.

Common Applications of Wrapping Machines in Various Industries

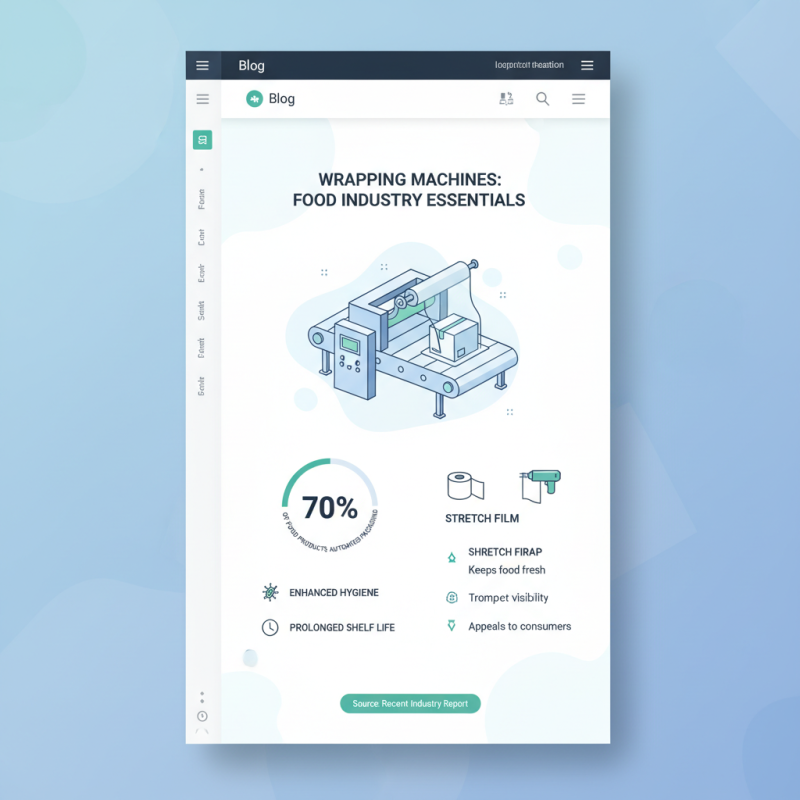

Wrapping machines play crucial roles in various industries, enhancing efficiency and protecting products. In the food sector, these machines are essential for packaging. According to a recent report, around 70% of food products are packaged using automated machines. This ensures hygiene and prolongs shelf life. The use of shrink wrap or stretch film helps keep food fresh and visible to consumers.

The pharmaceutical industry also heavily relies on wrapping machines. A study indicates that the global pharmaceuticals packaging market could reach $129 billion by 2024. These machines help in safeguarding medications from contamination. They also provide necessary labeling for ease of identification. However, there are challenges. Some packaging might not be as eco-friendly as required. Companies are under pressure to improve sustainability.

In the retail sector, wrapping machines are key in ensuring products are secure. They minimize the risk of damage during transportation. A significant concern is that some machines lack adaptability. They may not accommodate a variety of product sizes and shapes. As demand for customization increases, this limitation could lead companies to rethink their wrapping solutions.

Related Posts

-

Unmatched Quality from Trusted Chinese Manufacturers for the Best Package Equipment

-

Leading the World with Quality Chinese Food Packaging Solutions

-

Navigating the 2025 Trends in Best Packaging Equipment for Global Buyers to Enhance Efficiency

-

5 Compelling Reasons Your Business Needs the Best Packaging Equipment Today

-

Exploring Innovative Alternatives in Produce Packaging Machinery Solutions

-

5 Essential Tips to Maximize Efficiency with Your Package Machine